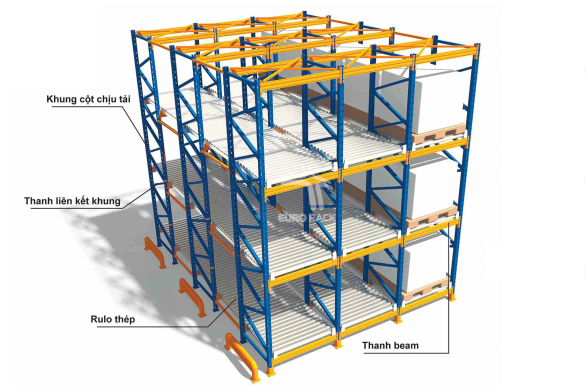

Pallet flow racking includes 4 basic details:

- Upright frames: Bearing for the whole system.

- Horizontal braces: Dispersing force between the upright frames.

- Load beams: Connecting between 2 upright frames.

- Rollers: Supporting pallets moving

Pallet flow racking are high density pallet storage systems that utilize depth to increase capacity.

This system uses a slightly inclined rail with rollers that allow pallets to move easily along the sloped plane.

Pallets move automatically with no energy consumption.

Pallet flow racking includes 4 basic details:

Design Standard

| Pallet (mm) | 800 x 1200 | 1000 x 1200 | 1200 x 1000 |

| Forklift Entry (mm) | 800 | 1000 | 1200 |

| Capacity (kg/pallet) | 1000 | 1000 | 1000 |

- Load: 1000 - 3000kg/ pallet.

- The height of the system is up to 10m.

- Increasing storage area by 60%.

- The entire system is powder coated under the European standards.

- Pallet flow systems are high density pallet storage systems that utilize depth to increase capacity. This system uses a slightly inclined rail with rollers that allow pallets to move easily along the sloped plane.

- The goods are placed onto the on-load face and are carried down by the force of gravity.

- The system reduces pick paths and increases picking efficiencies.

- Forklifts move easily in the aisles.

- Reducing aisle area to increase storage space.

- Suitable for most of forklifts on the market.

- Being popularly used in cold storage, pharmaceutical warehouse, that has a regular pallet specification.