Heavy duty rack

Heavy duty racking system is a material handling storage aid system designed to store materials on pallets (or “skids”), weighing from 500kg - 3000kg / Pallet.

Forklift trucks are usually required to store loaded pallets on racks.

There are many varieties of pallet racking, depending on the characteristics of products and storage needs.

Include the following racks:

The features of Radio Shuttle:

- Using 80% of the warehouse area.

- Transporting goods automatically in the system.

- Importing and exporting goods with high speed.

- Reducing the risk of collision and accident.

- Free to choose FIFO or LIFO.

- Withstand temperatures up to -300C.

The features of ASRS

- The most modern storage solution.

- Loading and unloading goods automatically.

- Saving investment costs by using only a robot.

- The management system is professional.

- Suitable for cold storage.

The features of Double Deep pallet racking:

- Increasing capacity from Selective Racking by approximately 30%

- 50% accessibility to individual pallets

- Using specific forklift

- Products can be stored up to four pallets deep

- Being designed under EN 15.512: 2009 (FEM Standards)

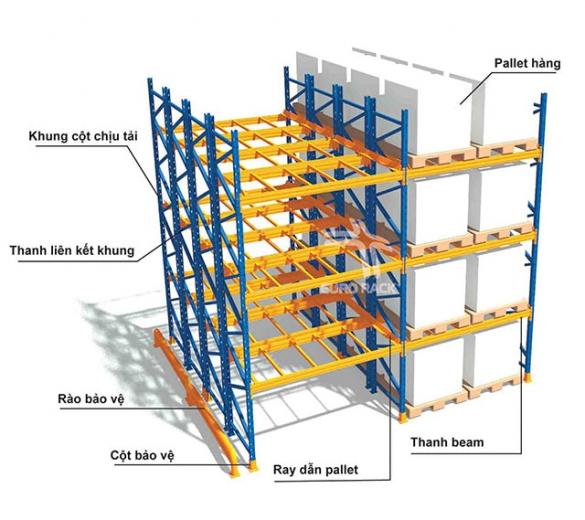

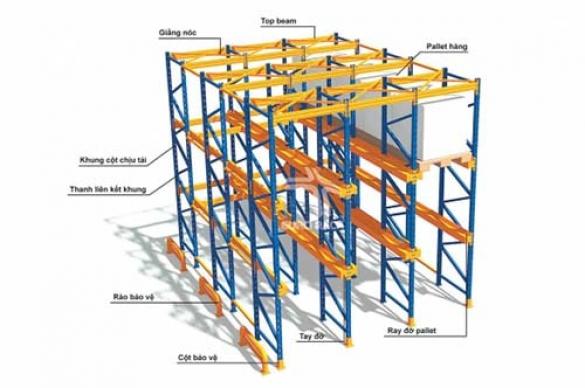

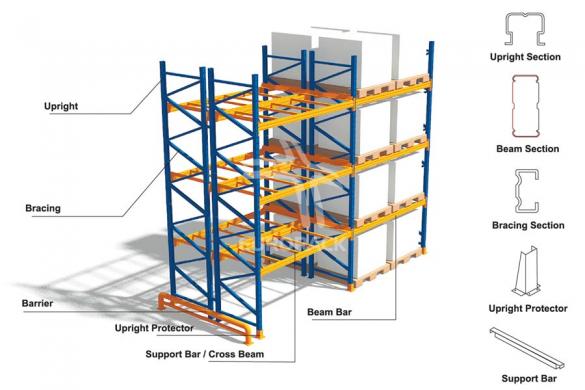

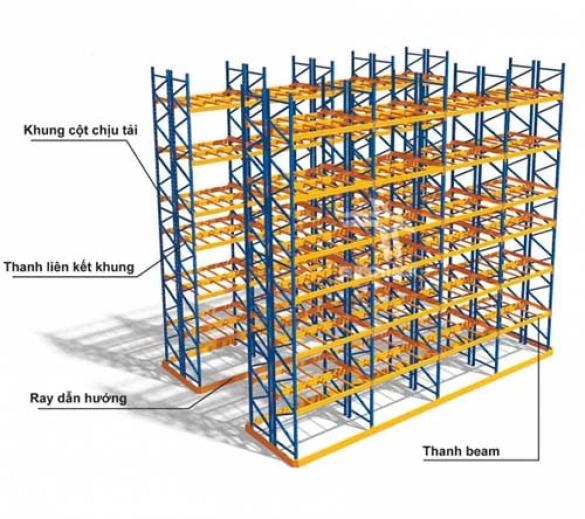

The features of Drive In pallet racking:

- Using 70% of the warehouse area.

- LIFO method.

- Low investment costs. Suitable for variety of forklifts.

- Can store goods with high density.

- Suitable for storing diverse goods. Easy to upgrade and expand.

- Designed according to EN 15512:2009 standards.

The features of Selective pallet racking:

- Designed for flexibility and provides immediate access of all pallets

- Provides high density storage

- Low investment costs

- Easy installation and re-configuration

- Can accommodate moving beam levels to adjust for new or different size pallets

- Has extensive line of accessories for a variety of applications

- Simple stock rotation achieved. Rapid handling of almost all types of palletized goods

- Suitable for most types of forklifts

The features of VNA racking:

- Best Configuration for maximum storage

- 100% accessibility to individual pallets

- Better utilization of space

- Lower occupancy rates per stored pallet

- Additional cost of specialist forklift truck offset by the added value of improved space utilization

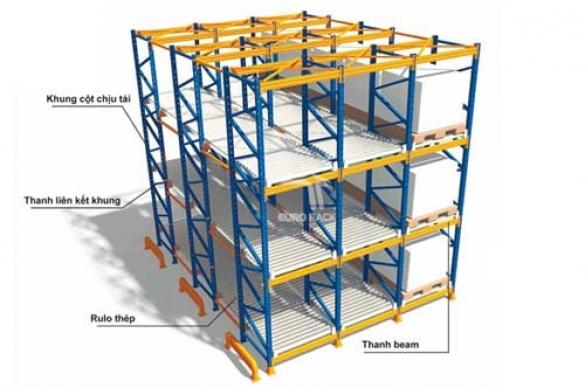

The features of Pallet flow racking

- Inventory control: First-In, First-Out (FIFO)

- Saving time and space in pallet handling

- Increasing storage area by 60%

- Loading on inclined end, unloading on opposite (declined) end

- Pallets move automatically along the sloped plane

The features of Push-back pallet racking:

- Storing large quantities of goods

- Providing the high-density storage system

- Ideal for LIFO product rotation strategies

- Loading and unloading the products from one side of the system

- Each cart is separate from each other, easy to identify and repair as needed

- Each bay can be from two to five pallets deep

- Average investment cost