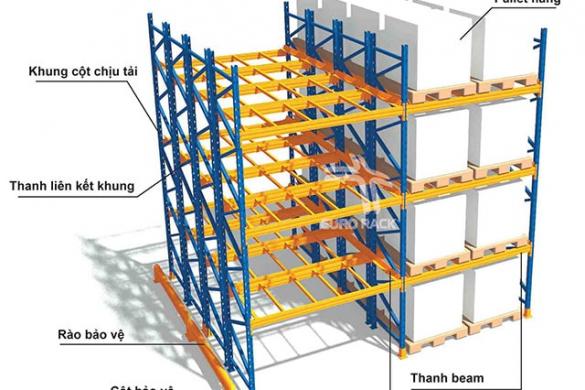

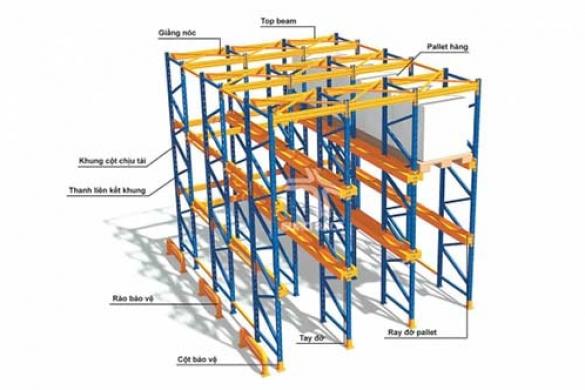

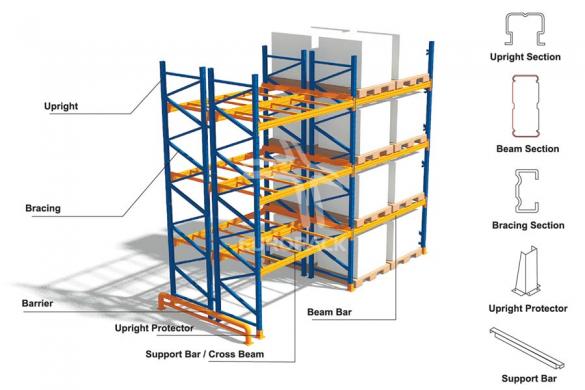

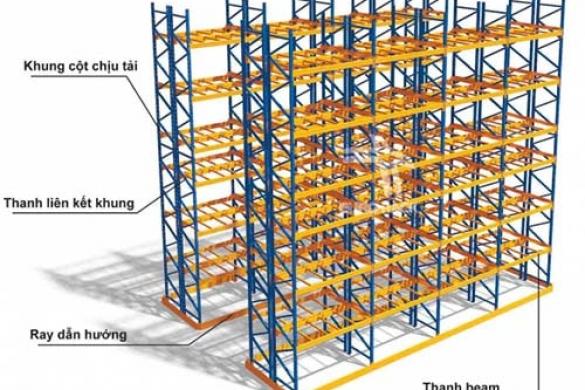

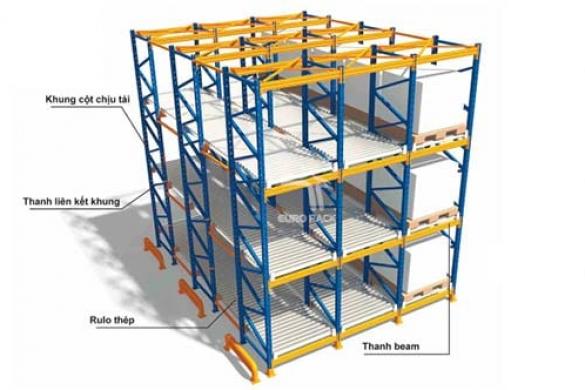

Radio Shuttle includes 6 basic details:

- Upright frames: Bearing for the whole system.

- Beam: Connecting between 2 upright frames and is the place to put pallets and guide rail.

- Guide rail: Placing radio shuttle car.

- Radio shuttle car: Loading goods in the system.

- Pallet rail splice: Immobilizing the guide rail.

- Rail-end stop: Keeping the radio shuttle car from sliding off the rack.