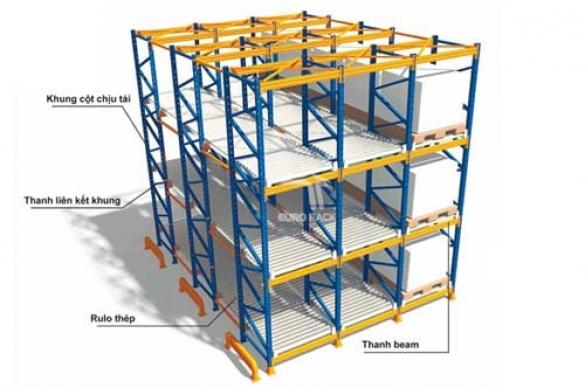

Pallet flow racking includes 4 basic details:

- Upright frames: Bearing for the whole system.

- Horizontal braces: Dispersing force between the upright frames.

- Load beams: Connecting between 2 upright frames.

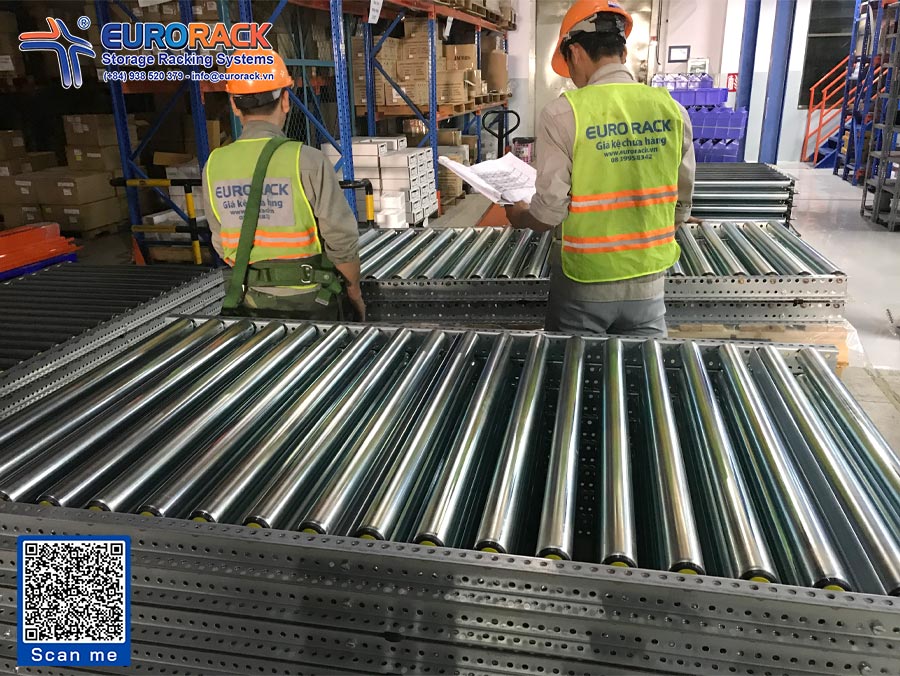

- Rollers: Supporting pallets moving

Pallet flow racking are high density pallet storage systems that utilize depth to increase capacity.

This system uses a slightly inclined rail with rollers that allow pallets to move easily along the sloped plane.

Pallets move automatically with no energy consumption.

Pallet flow racking includes 4 basic details:

Design Standard

| Pallet (mm) | 800 x 1200 | 1000 x 1200 | 1200 x 1000 |

| Forklift Entry (mm) | 800 | 1000 | 1200 |

| Capacity (kg/pallet) | 1000 | 1000 | 1000 |

- The shelf frame is designed with an inclined slope, with a difference of 1 - 3 degrees to operate the roller to move the pallet smoothly.

- Use a height of 10m, freeing up floor space for goods.

- Narrow forklift aisles, increasing storage area by 60%.

- The entire system is powder coated under the European standards.

- High density Flow Rack Pallet System, fast and safe loading and unloading with deceleration device.

- Provides European standard storage environment features and benefits.

- Suitable for all types of forklifts on the market, maximum savings in investment costs.

- Ideal for seasonal goods storage, food storage, pharmaceutical storage, short-term industrial semi-finished or finished product storage, etc.

- The shelf design slopes towards one side, the pallets follow inertia and slide towards the low side, shortening unloading time.

- When a pallet is removed from the system, the pallet immediately behind it immediately goes to the empty position.

- Pallets for automatic rotation of goods, controlling inventory waste.