Eurorack's powder coating process

Eurorack applies powder coating during the manufacturing process. This technology is increasingly widely used, because it has many outstanding advantages. Let's find out Eurorack's powder coating process through the following article.

Powder coating process of Eurorack

Powder coating process includes the following 5 basic steps: Drying, Powder coating, Curing, Cooling and Packaging.

State 1: Drying

Product surfaces are treated by chemicals before being powder coated. Therefore, they need to be dried to remove any remaining chemicals and water. The products are put in a curing oven for faster drying instead of drying naturally.

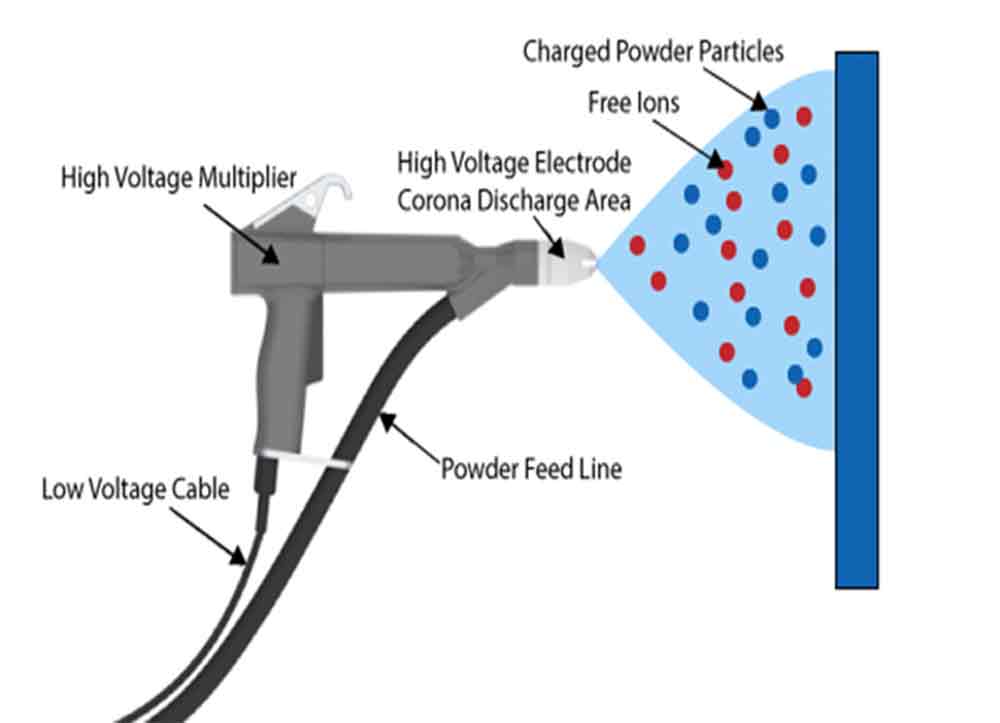

State 2: Powder coating

Eurorack uses paint guns to create of powder layer covering the surfaces of the items. The powder will cover and stick the surfaces of the goods due to applying electrostatically. Excess powder can be recycled, thereby helping to reduce product costs.

State 3: Curing

The goods after being powder coated are put in a curing oven to curing. This step makes the powder melt and the coating rigid and durable. Eurorack sets the curing temperature to 180 degrees.

State 4: Cooling

The items are cooled naturally after being moved from the curing ovens. Then, Eurorack checks the quality and resolves any problem. Our products meet the quality standards of TCVN 9276: 2012.

State 5: Packaging

Eurorack packaged products for better storage. This stage also helps to prevent damage caused by collision during transportation.

Advantages of applying powder coating process

1. Saving costs

The most outstanding advantage of powder coating is cost savings. 99% of powder is used thoroughly and the excess powder can be recovered and reused for later times. Besides, powder coating does not need the support from liquid solvent like traditional methods, which helps reduce input costs. As a result, Eurorack can reduce the product costs and customers can save the investment costs.

2. More durable

The quality of powder coating is superior to conventional methods. Due to applying electrostatically, it is one of the most economical, longest lasting, and most color-durable quality. In addition, the powder does not peel off in patches like water paint helps to improves the protection for the items.

3. Beautiful and aesthetic

Paint guns helps the powder adhere evenly to the surface and enhance the aesthetics compared to using the traditional paint method. In addition, the color spectrum of powder coating is also wider than that of water paint.

With the above information, Eurorack hopes you will understand our powder coating process. We are constantly researching and applying modern technologies to operation, with the aim of improving product quality and reducing investment costs for customers. If you have any questions, contact us to get advice from our experts.

Explore more: Metal surface treatment process

Contact Info:

Eurorack Mechanical Join Stock Company

Address: 5/3 Doan Thi Diem, Ward 1, Phu Nhuan District, Ho Chi Minh city

Phone number: (028) 39 953 088

Emai: info@eurorack.vn