The factors affecting the cost of selective racks

Selective pallet racking is a traditional heavy-duty racking system that is primarily used today. It is considered an industrial steel racking system with fairly optimal costs. This article will help you better understand the factors that determine the cost of this type of racking so that you can optimize it more effectively

The 10,000m² selective racking project carried out by Eurorack

| Mục lục nội dung: |

Selective racking overview

What is selective racking

Selective racking system is a type of pallet racking system made of steel, with each level capable of holding up to 9 tons.

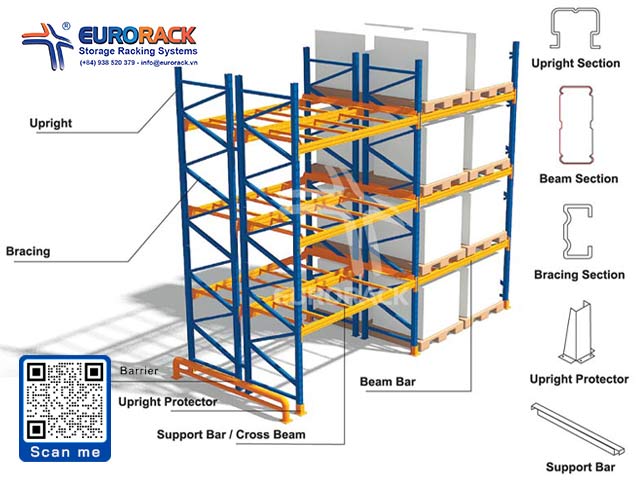

The basic structure of selective racking includes

- Main upright column: Responsible for supporting the entire racking system.

- Bracing beam: Helps distribute force and connects the two upright columns to maintain the stability of the rack.

- Beam: Connects the two upright columns, serving as the main load-bearing component where pallets are placed.

- Support bar: Enhances the stability of the beam and ensures the pallets are secured.

- Column protector: Links the upright column to the floor, ensuring the system's sturdiness.

- Safety guard: Protects the racking system from collisions with other equipment, such as forklifts.

Advantages and disadvantages of selective racking

Selective pallet racking is commonly used but also has its strengths and weaknesses. Below are the advantages and disadvantages of this heavy-duty racking system:

Advantages

- 100% pallet accessibility: Enables quick and flexible loading and unloading.

- Easy forklift movement: No special requirements for forklifts. The wide aisles facilitate easy loading and unloading, minimizing the risk of collision with the racking system.

- Versatile storage: Suitable for warehouses that need to store large quantities of goods with many SKUs. It can be used in material warehouses, production warehouses, finished product warehouses, industries, seafood, cold storage, logistics warehouses, and more.

- Space and cost-saving: Optimizes 30-65% of floor space, with low investment costs.

- High quality: Made from premium steel, with excellent rust resistance thanks to European-standard electrostatic powder coating.

- Flexible design: Easily adjustable rack compartments based on storage needs.

► See more: Comparison between Selective Racking and Double Deep Racking

Disadvantages

Selective racking does not optimize space well because it requires a lot of space for aisles. If the goods are large, long, or uniformly sized, this type of racking might not be the best choice. Additionally, installation costs can be high for large warehouses.

Factors affecting the cost of selective racking Selective racking is one of the storage solutions for industrial warehouses due to its selective and flexible nature. However, the cost to install and maintain a selective racking system is not insignificant.

Factors affecting the cost of selective racking

Selective racking is one of the storage solutions for industrial warehouses due to its selective and flexible nature. However, the cost to install and maintain a selective racking system is not insignificant.

Here are 9 factors to help you better understand and make appropriate decisions to optimize the cost of your warehouse:

1. Size and number of pallets in the racking system

The first factor that affects the cost is specifications of the selective racks. The larger the warehouse storage rack, the more materials are required, resulting in higher production and transportation costs.

For example, taller racks usually require more steel materials and thicker, sturdier support columns to ensure safety. Similarly, the width and depth of the racks also impact the total cost since larger dimensions require more materials and installation work.

Solution: Businesses should plan ahead regarding warehouse space, zoning, and inventory quantities to select the appropriate size and type of rack. Avoid upgrades or repairs that increase costs. Also, consider the characteristics of the products to choose the right rack size for safety.

2. Rack material composition

Eurorack selective racks are made from stainless steel with an electrostatic powder coating or hot-dip galvanizing. You can choose the surface coating method that best suits your needs. The method of coating the steel (iron) surface will also affect the cost.

Solution: To minimize maintenance costs and increase the lifespan of the racks, you should choose high-quality racks supplied by reputable brands.

Choosing materials with a good protective coating will help extend the lifespan of steel racks and reduce maintenance costs. Opt for high-quality steel racks, such as galvanized or corrosion-resistant electrostatically coated steel. While the initial cost may be higher, it will result in significant long-term savings.

3. Load capacity and safety requirements

Safety is considered the most important factor in a warehouse. For warehouses storing heavy loads, which can weigh several tons, this is a factor that should be carefully considered. It is important to use thick steel materials that meet standards and have load-bearing certifications.

The greater the load capacity, the thicker and more complex the rack structure needs to be.

Solution: Businesses should choose industrial steel racks suitable for the weight of the goods to be stored, ensuring both safety and cost savings.

Eurorack pallet racking load test video

4. Custom design

Selective racks have the advantage of being customizable to meet specific requirements. However, you need to manage this well to avoid unnecessary cost increases.

For example, if your warehouse can increase height instead of adding additional rack rows, choose this option from the start to avoid extra costs when upgrading.

► See more: Standard rack production process

5. Installation costs

Installing selective racks requires experienced and highly skilled personnel. Installation costs depend on the complexity of the racking system.

Therefore, it is advisable to choose well-established and reputable companies in the industry, like Eurorack. These companies typically have their own skilled technical and production teams, as well as professional installation crews. Additionally, they provide technical support and warranties in case of any issues during use. In the long run, this is a crucial factor that will help reduce maintenance costs.

6. Maintenance

Although maintenance is rarely needed, it’s important to schedule regular inspections to ensure the warehouse system operates smoothly. This will help minimize unexpected repair costs. Additionally, choosing high-quality racking systems will help reduce damage and significantly lower maintenance costs.

► See more: Eurorack pallet rack maintenance process

7. Brand and quality certifications

Brand reputation and quality certifications are factors that influence the price of racks. These companies invest in technology, materials, and a structured manufacturing process. Larger suppliers with ISO 9001:2015 certification and strong market reputations will have higher-priced racking systems compared to less-known brands. However, high-quality products that meet international safety standards, combined with professional after-sales services, provide customers with greater peace of mind.

This is a long-term investment, so it’s essential to choose reputable warehouse racking manufacturers.

8. Shipping time and delivery fees

The cost of transporting racks from the manufacturer to the warehouse is also part of the total cost. You should choose companies with headquarters in your region or country to receive better service support. At the same time, transportation costs and time will be reduced. To ensure progress, make specific construction and timeline plans before proceeding. Additionally, consider carefully when choosing companies that do not offer transportation services, as these costs can be significant.

9. Order quantity

The number of racks ordered directly affects the price per unit. When you install a larger quantity of racks, there is usually a better price offer. Conversely, ordering a smaller quantity can make the price per unit higher.

These are the basic factors that affect the price of selective racking. Additionally, depending on exchange rates, transportation costs, and material costs, prices will vary over time. You can refer to the cost of Eurorack's product lines at:

► Eurorack pallet racking price list (Latest update) ◄

For consultation on heavy-duty racks suitable for your warehouse’s actual situation and financial budget, please contact us directly through the following information: