2024 Genuine Eurorack steel pallet price quotation - European Standards

Along with storage racking, steel pallets provide professional support in the storage and transportation of goods in heavy-duty industrial warehouses. By using these pallets, businesses can significantly save costs due to the sturdy and durable structure of the pallets.

What is a Steel Pallet?

A steel pallet (metal pallet) is a flat metal item used to secure goods during storage. It keeps goods stable during lifting and moving processes, minimizing the risk of goods shifting or falling and ensuring safety.

Compared to plastic and wooden pallets, steel pallets have higher durability. In addition to their superior load-bearing capacity, steel pallets accommodate various lifting directions, styles, and types. Common types include powder-coated pallets and galvanized pallets.

In storage, steel pallets are combined with various types of racks to significantly increase storage density. Common steel pallet racks include Selective racks, Double Deep racks, Drive-In racks, Flow racks (roller racks), Very Narrow Aisle (VNA) racks, and more.

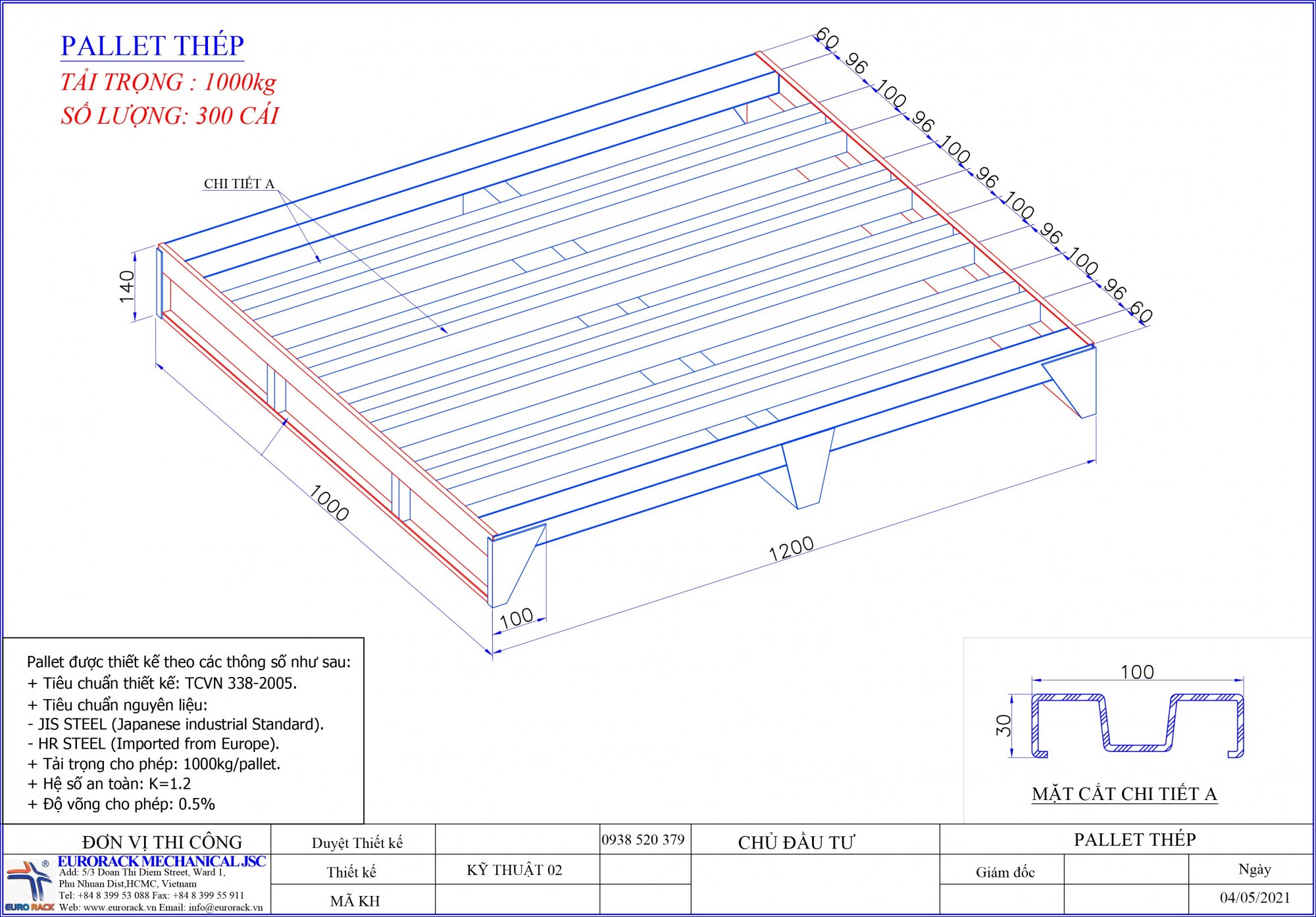

1. Technical specifications

If the storage of heavy goods is a concern for your business, steel pallets are a popular choice. These sturdy pallets offer stable load capacity and high durability, allowing for long-term applications of 10 - 15 years.

- Steel Pallet Sizes: 1000mm x 1200mm, 1100mm x 1100mm, 1200mm x 800mm, or 1200mm x 1000mm.

- Load Capacity: 500 – 3000 kg/pallet. Among them, the stackable steel pallet model has the highest load capacity, up to 4000kg.

- Material Thickness: Standard steel thickness ranges from 2mm to 10mm, depending on the required load capacity.

- Surface Treatment: Powder coating or galvanized for corrosion resistance. This provides hardness and durability to the steel pallet, suitable for various working environments.

Note: Technical specifications may vary based on practical requirements. Customers needing pallets, please contact Eurorack directly for suitable design consultation and cost-effective optimization!

2. Advantages of Steel Pallets Compared to Plastic or Wooden Pallets

Steel pallets have many advantages over plastic or wooden pallets, such as:

- Durability: Steel pallets do not break or suffer from rot and termites like wooden pallets.

- Load Capacity: Steel pallets have higher durability and load-bearing capacity than plastic pallets due to the stable hardness of the metal.

Specifically:

- Load Capacity: Steel pallets can hold up to 3000kg.

- Cold Storage Performance: They perform well even in cold storage environments down to -30°C.

- Longevity: Higher lifespan and resistance to deformation from forklift impacts.

- Low Damage Rate: Lower risk of damage, leading to higher economic efficiency.

- Versatility: Widely used in the storage and transportation industry.

Eurorack Video: Operating a Forklift to Load Test Stackable Steel Pallets with Metal Materials

Introducing Genuine Eurorack Steel Pallets

Eurorack steel pallets are made entirely from high-quality steel. They have a large load capacity of 4000kg per pallet, with surfaces treated with powder coating or galvanized to prevent rust. These genuine pallets can be stacked to save space and facilitate loading and unloading activities.

2. Why Should You Choose Eurorack Steel Pallets?

- Leading Pallet Manufacturer in Vietnam: Eurorack is recognized as a top producer of pallets in the country.

- On-Site Survey and Free Accurate Quotation: Eurorack offers precise, complimentary quotes after on-site surveys.

- ISO 9001:2015 Certified Product Quality: Ensuring high standards in production.

- Top Steel Suppliers: Eurorack sources steel from leading brands like Posco, Nguyễn Minh, and Hòa Phát.

- Sturdy and Robust Design: Superior load-bearing capacity.

- Modern European Production Line: Utilizing advanced technology.

- Japanese Powder Coating Standards: Ensuring durability and high-quality finishing.

Safety inspection of Eurorack steel pallets before delivery to customers in Vũng Tàu

Galvanized Steel Pallets and Powder-Coated Steel Pallets

The purpose of pallets is to enhance storage capacity on shelving systems and facilitate the safe movement of goods by forklifts and containers. Based on the metal surface treatment method, steel pallets are classified into two main types:

1. Galvanized Steel Pallets

Galvanized steel pallets are common storage pallets composed of multiple steel bars joined to form a flat structure. The surface of these pallets is treated with galvanization. The galvanized coating prevents corrosion, making the pallets resistant to impacts and capable of bearing heavy loads.

Galvanized steel pallets offer exceptional anti-oxidation benefits. They have an impressive load capacity of 2000kg per pallet. It's important to note that different galvanization methods result in varying levels of rust resistance.

Currently, there are two common galvanization methods:

- Electroplating: This method creates a thin zinc layer on the surface, which can easily peel off upon impact.

- Hot-Dip Galvanizing: This method applies a thick zinc coating, offering better protection for the metal.

Eurorack exclusively produces hot-dip galvanized pallets, so you can fully trust in our products!

Eurorack's steel pallet drawings offer optimal solutions for each specific usage requirement.

Common Sizes of Galvanized Pallets:

- L1200 x W800 x H150 (mm)

- L1200 x W1000 x H150 (mm)

- L1000 x W1200 x H150 (mm)

- L1100 x W1100 x H150 (mm)

The application range of galvanized steel pallets is extensive, including notable uses in pharmaceutical warehouses, cold storage, food processing warehouses, and bottled beverage warehouses.

Powder-coated pallets are metal pallets treated with powder coating technology. The coating prevents rust, ensuring the pallets' heavy load capacity and high performance. These pallets are durable for both outdoor and indoor storage use.

To achieve the best powder coating quality, steel pallets must undergo a strict surface treatment process using chemical baths. These solutions in the baths remove impurities, rust, and remaining oils from the surface.

In terms of load capacity, powder-coated pallets meet the storage needs of 1500kg for standard models. For stackable powder-coated pallets, the load capacity can be 2-3 times higher. However, in terms of durability, galvanized pallets are more ideal than powder-coated ones.

> > > See more: Eurorack's Standard Powder Coating Process

Common Powder-Coated Pallet Sizes for 2024:

- L1000 x W1000 x H140 (mm)

- L1000 x W1200 x H150 (mm)

- L1100 x W1100 x H150 (mm)

- L1100 x W1200 x H150 (mm)

To save costs, powder-coated pallets have become the top choice for pharmaceutical, food processing, petroleum, chemical, and heavy industry warehouses.

Types of steel pallets for heavy-duty storage racks

Many investors often ask about the types of steel pallets available. Eurorack has compiled detailed information on the main types of genuine steel pallets commonly used in heavy industry today:

1. Stackable Steel Pallets

Stackable steel pallets, also known as reverse stacking pallets, are designed with sturdy support legs made from high-quality steel. Their fixed welded construction makes them robust and capable of stacking up to 5 levels high. Each pallet layer functions as a shelving layer, helping businesses save on storage rack investment costs.

Technical specifications of stackable pallets:

- Pallet height: 2.5m - 4.5m

- Stack height: 2 - 5 levels

- Average load capacity: 1000 – 3000kg/pallet

Stackable Steel Pallets Applications: Stackable steel pallets are widely used in various fields: construction industry for storing cement materials, steel coils, warehouse storage for fabric rolls, and wheels.

Advantages of Stackable Pallets:

- Direct Storage: Store goods directly on the pallet without the need for additional racks.

- Four-Way Access: The base design allows forklifts to access from four directions conveniently.

- Space Efficiency: Effective in both large and small spaces.

- Versatile Storage: Supports the storage of various types of goods.

- Compact Nesting: Easily nested when not in use to save space.

2. Foldable Steel Pallets

Similar to the standard stackable model, foldable pallets also function as a support tier. The distinctive feature of this pallet type is that the parts are connected via bolts, making them very flexible. This allows the pallet to be easily assembled or disassembled and folded compactly when not in use.

Technical Specifications of Foldable Pallets:

- Stacking Height: Can be stacked 2 to 3 layers high.

- Average Load Capacity: 500 – 2000kg per pallet.

- Compact Storage: Foldable and stackable when not in use.

Foldable stackable steel pallets offer numerous outstanding advantages for heavy-duty storage applications, particularly popular in the automotive, metalworking, textile, and fabric storage industries.

Advantages of Foldable Stackable Pallets:

- High-Quality Steel Frame: Durable and safe under sub-zero temperatures.

- Convenient Storage: Easily foldable and stackable when not in use.

Eurorack personnel installing reverse stackable pallet frames for a large fabric roll warehouse

3. Mesh Steel Pallets

Mesh steel pallets feature rectangular steel mesh frames with an open top, minimizing mold growth while storing goods inside. The ventilated design allows managers to easily observe and locate products when needed, while also preventing goods from spilling.

Technical Specifications of Mesh Steel Pallets:

- Load Capacity: <1000kg

- Mesh Openings: Rectangular holes 50mm × 25mm for ventilation

- Design: Convenient side panels that can be opened or closed for easy access to goods.

Wire mesh steel pallets are the top choice for storing and transporting boxed products, metal items, plastic goods, and agricultural produce. They are especially versatile for use in supermarkets and garment processing workshops.

Advantages of Mesh Steel Pallets:

- Can be fitted with springs and flexible folding doors.

- Pre-installed wheels make moving the pallets easy.

4. Steel Box Pallets

Steel box pallets (steel containers) are designed with four closed steel frames on the sides, resembling a metal box for holding goods. These closed sides prevent spillage and provide protection from unwanted impacts.

Technical specifications of Steel Box Pallets:

- Load Capacity: 2000 - 6000kg per pallet.

- Dimensions: L600 or L1200 x W1200 or W2400 x H850 (mm).

- Steel box pallets are widely used in warehouses for components, tools, heavy equipment, and items with long, tubular, or box-like shapes.

While standard steel pallet sizes are quite common, the best design approach varies based on different usage purposes. For the most optimal design, please contact Eurorack immediately!

Best Eurorack Steel Pallet Prices for 2024

Today, the application of metal pallets is becoming increasingly popular across many industries and sectors. To help customers estimate the total investment costs for their warehouses, Eurorack provides the latest factory price updates:

[Include the latest price list here]

For more information and to get the best quotes, please reach out to Eurorack directly!

| STT | Pallet Type | Price (VND) |

| 1 | Galvanized pallet | 750.000 - 2.250.000 vnđ/pallet |

| 2 | Powder-coated pallet | 750.000 - 2.050.000 vnđ/pallet |

| 3 | Stackable pallet | 1.750.000 - 3.500.000 vnđ/pallet |

| 4 | Foldable stackable steel pallet | 1.650.000 - 2.750.000 vnđ/pallet |

| 5 | Mesh steel pallet | 950.000 - 2.150.000 vnđ/pallet |

| 6 | Steel pallet box | Contact for price |

In reality, each pallet has specific size and material standards, so prices may vary. For the most accurate steel pallet price consultation, please contact 0938.520.379 directly. Eurorack offers stable pricing consultations and attractive discounts, providing you with the best options!

Summary of Genuine Eurorack Steel Pallet Projects

Eurorack specializes in manufacturing genuine, affordable steel pallets with a variety of models. Below are some recent projects implemented by Eurorack. We invite you to explore more with Eurorack:

Important Notes on the Use and Maintenance of Steel Pallets

Steel pallets are known for their high durability compared to pallets made from other materials. However, to ensure that the pallets in your warehouse last longer, consider these three important notes:

Do Not Exceed Load Capacity:

High load capacity is a significant advantage of steel pallets. However, consistently exceeding the allowable load capacity over time is not advisable and can lead to damage.

Maintain Safety and Friction Factors:

Steel pallets are meticulously welded and surface-coated to minimize the risk of rust. However, prolonged use and collisions with forklifts can wear down the paint or dent the steel frame, reducing friction and making them harder to use. Regularly check the safety factor of the pallets and ensure they meet the highest quality standards during use.

Store Steel Pallets in Appropriate Conditions:

Ensure that the storage area for the pallets is well-ventilated and dry. Environmental moisture on the pallets can accelerate the oxidation process, leading to rust.

The above information provides an overview of Eurorack steel pallets. However, due to the diverse nature of the product, to find the optimal design in terms of both quality and cost, please contact us directly:

Contact Information:

EURORACK MECHANICAL JOINT STOCK COMPANY

Address: 5/3 Doan Thi Diem, Ward 1, Phu Nhuan District, Ho Chi Minh City

Email: info@eurorack.vn

Tel: (+84) 938520379