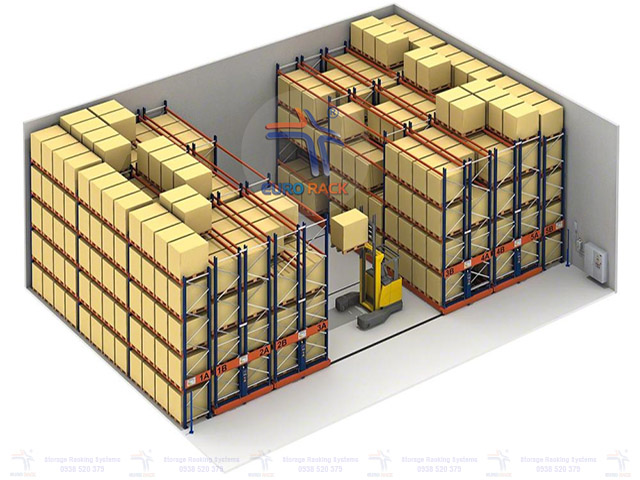

Mobile racking system smart solution to optimize smart space

In the context of increasing land prices and the demand for storage and preservation of goods in warehouses also increases. This proves that optimizing storage space is extremely important, based on which Mobile Racking System was born as a solution to effectively remove this problem. Let's go to learn more about its technical characteristics as well as its benefits below.

|

Mục lục nội dung: |

What is mobile racking system?

Mobile Racking System is a warehouse storage system in which rows of shelves can move across each other. This helps to optimize space by eliminating fixed aisles between rows of traditional shelves. In addition, thanks to its unique operating mechanism, the system is able to create the necessary passage (a desired distance to be customized by the user) for easy access to goods.

Specifications of Mobile racking system

The impressive parameters of Mobile Rack have made product consumption more and more popular such as:

Each shelf can hold up to 6000kg, while the average Mobile Rack has from 4-7 floors, equivalent to the capacity of a shelf range from 24000 - 42000 kg.

The number of Mobile Racks depends on the size of the warehouse, so there is no limit to the quantity. Normally, the scale of a warehouse using Mobile racking system is from 10-16 rows of shelves.

And yet, the shelf has an ideal depth of 40 - 70 m, which is very suitable for warehouses with many different product codes.

The moving speed of the shelf on the guide rail is 3.5-4.5m min. Days are approximate as they can be faster if you use a better engine.

The time to extend the distance at the row of shelves to be picked up is less than 50s.

Warehouses only need to use ordinary forklifts to be able to operate goods flexibly in and out of the system.

Operate well in harsh environments such as cold storage, with low temperature from -20 degrees.

Features and highlights of Mobile Racking System

Rack operating mechanism

Pallet Mobile racking will automatically move by remote control via handheld remote or using the control panel mounted at the top of each shelf row. Below is the step-by-step process of operating the shelf.

B1: Select a row of shelves to carry out loading and unloading of goods

You can easily select a row of shelves containing the item you need to load and unload and press the button with the corresponding number to activate it.

B2: Open the way

Once activated, the shelves will automatically open and they will automatically stop when they come close to another row of shelves, or have run out of rails. To do that, of course, they will be equipped with sensor eyes.

B4: Proceed to move into the aisle

At this step, the forklift operator will move inside to perform the picking of the goods, do not worry that the rack will close while the staff is picking up the goods, because they are blocked by the goods. Safety fence, above all, there is an emergency stop button.

B5: Get out of the aisle

After loading or unloading the package, the forklift will move out of the system in preparation for the return step.

B6: Rearrange the system

After the forklift has moved completely out of the aisle, the operator will activate the return button, and the whole system will be closed to its original position.

In addition, for the convenience of walking around, or performing inventory work, the shelf also integrates a selector mode that opens multiple aisles at the same time and stops when the user feels the distance. between rows of shelves enough to carry out the work. This shows great flexibility because depending on the purpose of the job, there will be many options.

Easy to control with friendly interface

Mobile storage rack is designed with a friendly user interface, making it easy for managers to monitor and control the entire system. Adjusting the manipulation of moving shelves becomes simple, ensuring efficiency and accuracy during operation.

Safety warning system

Mobile storage also integrates a safety warning system to help prevent accidents and ensure the safety of users. When a problem or unexpected situation occurs, the system will automatically issue a warning signal to prevent any danger.

To increase the peace of mind for users, the control panel installed on the system and the handheld remote also has a red button, representing the emergency stop function.

Mobile Racking components

The structure of this shelf line is also different from the traditional racking system, because of its flexible movement. A mobile rack system includes the following main parts:

- Iron rack system: This is the main load-bearing frame of the system, helping to maintain stability and safety for welding during operation.

- Brackets: Provides support for the shelving system, ensuring stability for the entire shelf

- Guide rails: Guide rails help the racking system move in line along the way. Normally, a shelf with a length of 50m will have 5-6 guide rails, depending on the size of the shelf, the number of rails may be less or more.

- Motor: The movement control motor of the system used is an electric motor with large capacity, ensuring enough force to be able to move the whole system weighing up to tens of thousands of kilograms. Due to the use of electric energy, there is no emissions, so it also contributes to making the air in your warehouse cleaner.

- Main electrical box: This is where control devices, circuit boards and other electrical equipment are stored to manage the operation of the system.

- Integrated control panel on the shelf: Allows the user to easily control and adjust the system on the spot.

- Handheld Control Panel: The mobile control unit allows the manager to control the system remotely.

Operating environment conditions

Mobile Racking warehouse works effectively in a variety of environmental conditions, from cold storage to dry storage. This ensures flexibility and stability in goods storage, but is also suitable for most areas from industrial warehouses to manufacturing, factories, factories, logistics, etc.

Benefits of Mobile shelving system

Increase storage capacity in the warehouse

The Mobile storage system allows to make the most of the space in the warehouse, increasing the storage capacity of goods from 80 to 120% compared to other conventional shelves without expanding the area.

Great load capacity

With sturdy design and high quality iron material, Mobile shelving system has a large load capacity, ensuring the safety of goods and employees.

High accessibility to goods

It is the only high-capacity storage system that meets the requirement of direct and precise access to each item placed on the shelf. Thereby helping to optimize in terms of time and effort.

Energy Optimization

Through the use of more optimal storage area, the amount of fuel such as electricity, refrigerant gas, and some other equipment such as lights, etc. will be less.

Good quality, safe to use

Fully equipped with automatic features and safety sensors, to help protect workers and create a safe and quality working environment.

Mobile rack app and positive reviews

This system has been successfully applied in many industries, from cold storage, manufacturing plants to distribution centers. Businesses have noted outstanding performance and optimization in inventory management and storage.

In a meeting with specific customers at the exhibition, we asked them if the Mobile storage product is still in good use? Are there any problems while using it? Of course the answer is absolutely yes and they are not afraid to express their satisfaction and also let us know about the upcoming project and they will still choose that product for their inventory.

>>>See more: Racking quotes of Eurorack.

Why buy Eurorack's Mobile racking system?

The first thing to mention is that Eurorack's system has strictly and fully complied with strict quality standards. Ensure product performance and durability.

Next is technology, Eurorack uses automatic production line technology, imported from Europe, along with the team's in-depth knowledge, creating superior products both in terms of technique and aesthetics.

In addition, Eurorack also has a policy to support customers at the stage of consulting, surveying and installation, to ensure that the system is deployed in the most optimal way.

When the works are completed, Eurorack has a commitment to warranty and maintenance policy to bring stable performance throughout the period of use as well as to create absolute peace of mind for customers.

The trust from exclusive partners such as Nestle, Pepsico has confirmed the prestige and quality of Mobile racking system from Eurorack.

Mobile racking is not simply a solution to optimize storage space, but also a combination of technology and innovation in inventory management. With outstanding advantages and compatibility with all industries, Mobile shelving system will become the storage trend in the future.

Contact Info:

EURORACK MACHENICAL JSC

Office: 5/3 Doan Thi Diem, Ward 1, Phu Nhuan District, HCMC

Email: info@eurorack.vn

Tel: 0938 520 379

>>> See more: Double deep racking system smart warehouse solution.