How to design a warehouse racking layout for your business?

How to efficiently store goods and maximize the amount of goods in the warehouse? This is always a problem which a lot of enterprises concern. You have to arrange the racks so that the storage capacity is increased and forklifts can easily move in warehouse. Eurorack will help you learn about how to design a warehouse racking layout through the following article.

Determining warehouse design

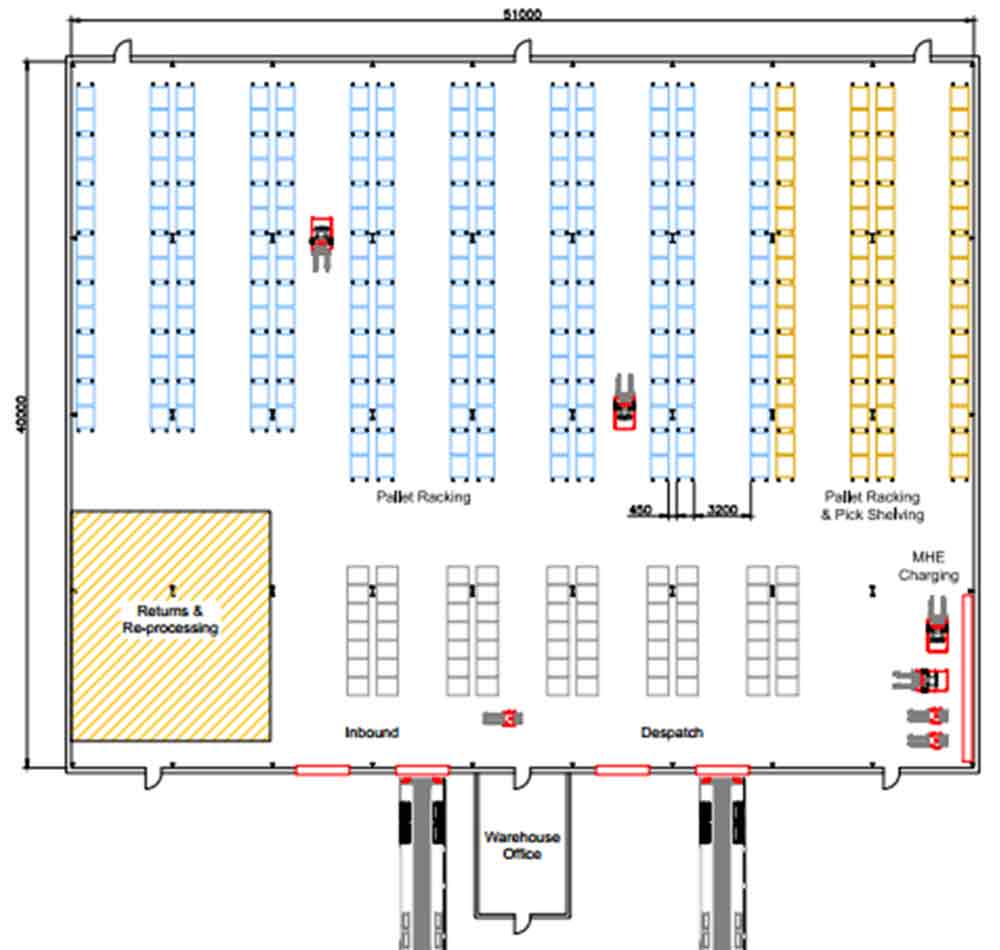

To find the optimal layout solution for your warehouse, you need to determine in detail its structure. In particular, you have to calculate the warehouse are, the height fo roof, the position of the entrances and the columns... These tips will help you choose the right warehouse racking systems for your company.

The racks are usually located near entrances so that the transporting process takes place quickly and conveniently. In addition, how to design a warehouse racking layout, you should also pay attention to the position of the columns to arrange the racking system so as not to obstruct the forklift when moving.

After learning about the warehouse layout, you divide the area inside the warehouse. You first have to determine where the products are handled and the management area.

Loading and unloading area is the place where goods are sorted and put on pallets before being transported onto the racking system. Furthermore, this is also the place to focus the goods before moving them to the outside. Therefore, this location should be located right at the entrances to shorten moving time. In some cases, businesses separate them into entrances and exits.

The warehouse management area may be located next to the loading and unloading area or an independent area from the warehouse. This department is responsible for inventory management, quality control, handling arising issues ...

We arrange racking system on the remaining area after arranging for the two above areas. For some businesses, the warehouse can be built with the factory. Consider these factors in calculating the location of racks!

How to design a warehouse racking layout according to dimension of forklifts

There are usually 1 to 2 main aisles with many small ones in each warehouse. Each type of forklift has different dimensions, so the minimum width required for aisles are also different. This has a great impact on arranging racks.

Dividing storage areas for each type of product

When businesses have multiple product categories, you have to consider the characteristics of each them to design the appropriate warehouse layout. Products with short shelf life or need to transport continuously should be placed as close to the main aisles as possible. Or heavy items with bulky dimensions should be placed near the entrance to the loading and unloading process can take place conveniently.

Explore more: How to choose the right storage rack for your warehouse

Contact Info:

Eurorack Mechanical Join Stock Company

Address: 5/3 Doan Thi Diem, Ward 1, Phu Nhuan District, Ho Chi Minh city

Phone number: (028) 39 953 088

Emai: info@eurorack.vn