Production process of high quality and durable heavy duty rack

Any warehouse needs an inventory storage system, how are the production process of high quality and durable heavy duty rack. Storage racking system are “essential assistants” that help solve the problem of arranging and preserving large quantities of goods without expanding the warehouse area. So, how are storage racks manufactured to ensure quality, heavy load capacity, durability, and high safety?

| Content |

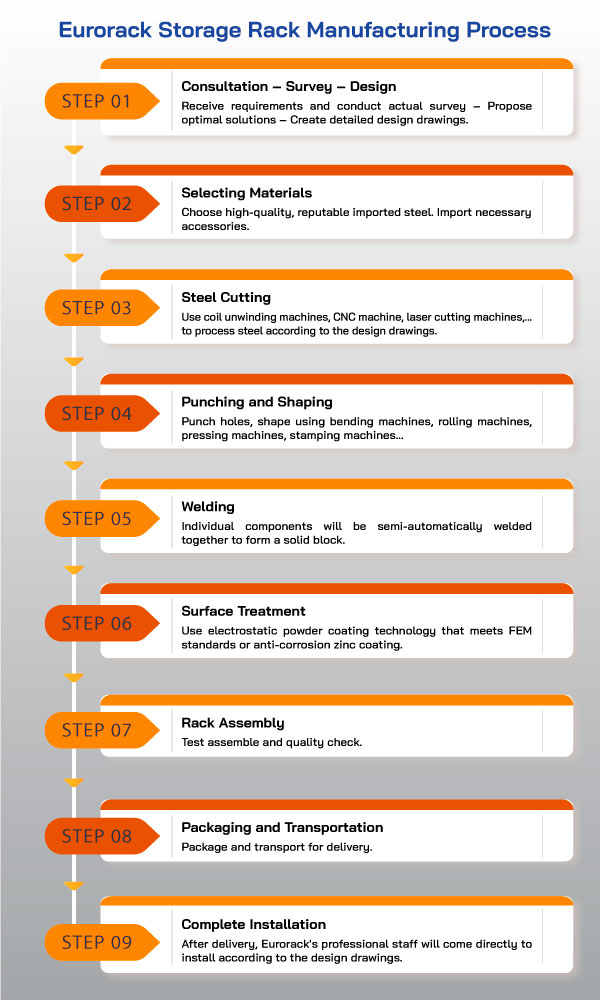

The manufacturing process of warehouse storage racks at Eurorack

If you have ever used storage racks, you must have heard of the European FEM standard and the international ISO quality standard. Products that meet these standards are guaranteed to achieve high quality and safety.

► Read more: What is the ISO Standard? The Latest Standards

Eurorack is one of the pioneering companies in Vietnam that directly imports and manufactures warehouse racks according to the EN standard. Applying Japanese technology and mastering the most advanced production machinery, Eurorack's warehouse rack products always satisfy customers. Below is the Eurorack warehouse rack manufacturing process:

Step 1: Consultation – Survey – Design

After receiving the request, Eurorack's technical and sales specialists will contact you directly. We will provide optimal warehouse space solutions according to customer requirements, offering plans that bring the highest economic efficiency.

► See details at: Quotation Eurorack Warehouse Rack Consultation

Step 2: Selecting Materials

Eurorack says no to low-quality products. Therefore, we pay great attention to the sources of materials. Eurorack only imports iron from reputable brands such as: Hoà Phát, Posco. Below is some information to address customer inquiries about: “Where does Eurorack import iron (steel) from? Is it reputable and safe?”

Eurorack imports coil steel, hot-rolled steel HRC from Hoà Phát, Posco. These are all leading reputable Vietnamese brands. Eurorack commits to saying NO to price dumping or quality reduction. The type of steel we use usually has a thickness of 18mm, meeting the standards for hardness and durability.

Accessories: Select accessories such as screws, bolts, and other high-durability and corrosion-resistant connection details.

Step 3: Steel Cutting

Eurorack uses coil unwinding machines, CNC cutting machines, laser cutting machines, table cutting machines, etc., to cut steel to the required sizes. For components and parts with high complexity, we will use CNC laser cutting technology to achieve higher precision.

Step 4: Punching and Shaping

To punch holes and shape the components of the storage rack, we use mold shaping machines (such as bending machines, rolling machines, pressing machines, stamping machines, etc.). After shaping the steel bars according to the design, ensuring all corners are even and accurate, we use laser punching machines to punch holes in the bars, ensuring the precision of the size and distance between the holes. Therefore, when the industrial warehouse rack is completely installed, it will be easier and more durable.

Step 5: Welding

Individual components will be semi-automatically welded together to form a solid block. This welding process ensures the welds are even and precise.

At the end of the raw production stage, we will check the welds again. The welds must ensure there are no holes or defects.

Step 6: Surface Treatment

To increase the protection of the steel, we will conduct surface treatment.

First, the oil and dirt layer must be cleaned off. Clean them using specialized solutions and equipment.

Then, spray paint: Use zinc paint to spray on the welds, preventing corrosion and enhancing the aesthetics of the product.

Step 7: Rack Assembly

Test assembly: Assemble the parts into a complete steel rack to check the accuracy and stability of the rack.

Then, conduct quality inspection: Re-check the entire product to ensure there are no errors and that it meets quality standards, concluding the manufacturing process at the factory.

► Read more: The process of inspecting standard storage racks

Step 8: Packaging and Transportation

Packaging: Use packaging materials such as nylon wrap, shrink film, and cartons to package the products. Ensure each product detail is safely protected during transportation.

Contact customers & deliver: Eurorack arranges to transport the products to the customer's warehouse or delivery location.

Step 9: Complete Installation

Upon completing the manufacturing and delivery process, Eurorack will have a professional team directly install according to the design drawings.

Thus, Eurorack's warehouse storage rack manufacturing process is strictly controlled from the material selection stage. Therefore, Eurorack storage racks always reassure customers about high quality and durability. At the same time, they comply with international safety standards, from materials, coating, technical technology, warehouse rack size, etc.

To be consulted – quoted for the appropriate warehouse storage rack line, customers can directly contact Eurorack at the following information:

Eurorack Mechanical Joint Stock Company

Tel: 028 39 953 088

Hotline: 0938520379

Email: info@eurorack.vn

Address: 5/3 Đoàn Thị Điểm, Ward 1, Phu Nhuan District, Ho Chi Minh City

► Learn more about Eurorack steel pallet manufacturing process: Here