Quotation for Eurorack medium-duty racking with Japanese Technology

Medium-duty racking is among the most commonly used in small to medium-sized warehouses. This range of industrial-grade metal racking for light to medium loads features a simple structure. The frames are connected with bolts and screws, making the racking highly flexible and easy to dismantle and move when necessary. Below is an overview of the medium-duty racking types that incorporate Japanese technology with advanced production lines, along with direct factory pricing.

| TABLE OF CONTENTS |

Overview of Medium-Duty racking

Applications of Medium-Duty racking

This model is currently the most popular type of warehouse racking. It is used in most warehouses, from residential to industrial settings.

Structure of Medium-Duty racking

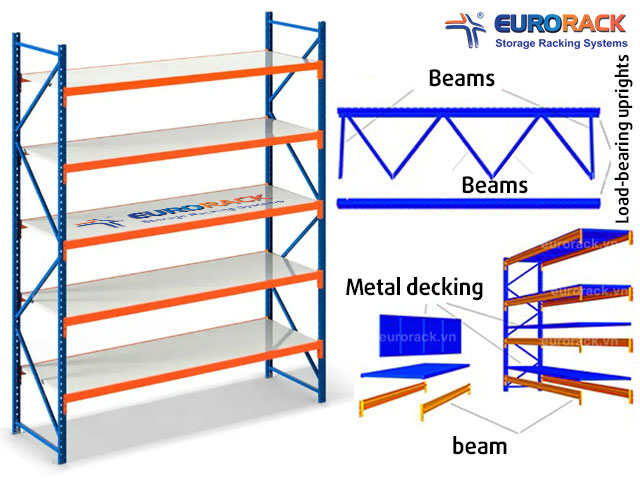

Similar to other industrial racking types, medium-duty racking comprises five basic components:

- Load-bearing uprights: Serve as the load-bearing columns and stabilize the racking.

- Frame linking bars: Distribute the force among the columns.

- Beams: Connect between two load-bearing frames and also support the racking boards.

- Metal or wooden decking: Designed as full sheets sized to customer specifications. These are the surfaces where goods are placed.

- Protective columns: Connect the load-bearing uprights to the decking, enhancing the system's stability.

Competitive Advantages of Medium-Duty Industrial racking

- No need for special forklifts. Goods can be manually placed on the racking.

- High durability and strong, load-bearing frames.

- Quick and flexible assembly and reconfiguration as needed.

- Easy to clean and low maintenance costs.

- Allows for pallet storage at the base, reducing costs while providing direct access to 100% of the goods.

- Maximizes space utilization in any warehouse configuration.

Types of Medium-Duty Warehouse racking

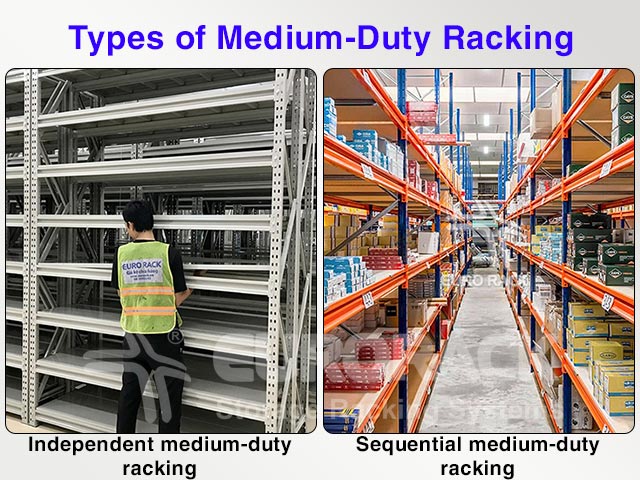

Medium-duty racking is designed to be simple, easy to assemble, and highly flexible. Its diverse models, attractive colors, and high durability are significant advantages of this range of light to medium load racking. Depending on specific features, it is divided into various types.

Division by Technical Features

- Independent medium-duty racking

- Sequential medium-duty racking

Independent medium-duty racking consists of separate systems. In contrast, sequential (dependent) medium-duty racking shares uprights on both ends, saving warehouse space and costs compared to independent systems.

Division by Number of racks

Each shelf level is counted as one tier. The most common include:

- Two-tier medium-duty racking: Supports a significant load capacity. Suitable for storing large-sized goods and boxes.

- Three-tier medium-duty racking: Features three levels with considerable space between them, suitable for storing a large volume of goods.

- Four-tier medium-duty racking: Also among the more affordable medium-duty options, offering good storage density with four levels.

- Five-tier medium-duty racking: Typically has smaller spaces between levels compared to three-tier systems but can store two to three times the volume of goods.

- Six-tier medium-duty racking: An efficient space-saving solution. Its load capacity and storage volume make it highly popular.

- Eight-tier medium-duty racking: Typically designed to be over 2000mm high, suitable for storing a wide variety of goods in large quantities.

As the number of tiers increases, so does the storage capacity. However, the load capacity per tier may decrease, and storing excessively high items beyond the space between two levels is not feasible. Thus, choosing the right type of medium-duty warehouse racking depends on the size, quantity, and weight of each item.

However, medium-duty racking typically does not exceed eight tiers to ensure safety.

> > > See more: Medium-duty racking

Price Quote for Eurorack Medium-Duty racking - New Update for 2024

The price of medium-duty racking varies with the number of tiers, dimensions, and other technical requirements. Generally, customers prefer three-tier, five-tier, and six-tier systems as they suit a variety of goods and larger dimensions or higher-tier designs exceeding the standard specifications mentioned above, please contact Eurorack directly via the Hotline: 0938 520 379.

Quotation of Independent medium-duty racking and Sequential medium-duty racking (updated in 2024)

|

Specification |

Price (vnđ/set) |

|

D1500 x R600 x C2000 |

2.500.000 - 3.150.000 vnđ |

|

D1600 x R600 x C2200 |

2.650.000 - 3.350.000 vnđ |

|

D2000 x R500 x C2000 |

3.250.000 - 3.750.000 vnđ |

|

D2000 x R600 x C2000 |

3.350.000 - 3.950.000 vnđ |

|

D2000 x R700 x C2000 |

Contact with us: 0938 520 379 |

|

D2000 x R800 x C2200 |

Contact with us: 0938 520 379 |

|

D3200 x R600 x C2000 |

Contact with us: 0938 520 379 |

|

D3500 x R1000 x C2000 |

Contact with us: 0938 520 379 |

For larger sizes or more design floors, higher than the standard specification, please contact Eurorack directly at Hotline: 0938 520 379

Where to Buy Authentic and Reliable Medium-Duty racking

Medium-duty warehouse racking is widely sold on the market, with each type priced differently according to quality. Electrostatically painted medium-duty racking is considered the best-selling product currently due to its high quality and durability.

Eurorack is a leading enterprise in the production of medium-duty warehouse racking. Eurorack's racking is manufactured using Japanese technology and European standards, with standard dimensions including: 900mm, 1800mm, 2400mm, 3000mm, meeting all customer needs. All products are produced through a scientifically advanced five-step electrostatic painting process. Basic colors are widely available, making it easy for customers to choose, such as: blue, orange, black, white, ...

> > > See more at: Eurorack's powder coating process

All racking units are tested and approved, widely applied in the industrial racking sector today. Under this standard, Eurorack accurately measures system information and data. The load-bearing capacity of this medium-duty racking can reach 1000kg.

Eurorack Medium-Duty Warehouse racking Projects

Aiming to produce quality products at the most reasonable prices, Eurorack is ready to invest in importing modern machinery and maintaining technological autonomy. This allows us to provide excellent products at the lowest possible cost.

Below are some images of large Eurorack medium-duty racking projects