Selective Racking and Double Deep Racking: Which Is the Better Choice?

Selective Racking and Double Deep Racking are not unfamiliar terms, but many people still confuse the two. Why is there confusion? What are the advantages and disadvantages between Selective and Double Deep, and which is the most efficient storage solution?

Selective Racking and Double Deep Racking: Which Is the Better Choice?

Selective Racking and Double Deep Racking: Which Is the Better Choice?

| Mục lục nội dung: |

I. Selective Racking

Selective Racking, also known as pick rack, is a type of industrial pallet rack with a flexible design suitable for most warehouses.

Features

Structure:

Selective Racking is the most commonly used pallet racking system today. With a very simple design, the rack is constructed from the following six basic components:

- Load-bearing upright frames: high-strength steel bars supporting the entire system.

- Beam connectors: connect two load-bearing frames, distributing force between them.

- Beam: connects two load-bearing frames, providing a place to put pallets.

- Support beam: connects two beams to keep the pallet stable and prevent it from slipping out of the system.

- Column protectors: reduce friction between load-bearing columns and the floor, keeping the system stable.

- Guard rails: protect the system from collisions with other equipment.

Selective Racking optimizes diverse storage space for goods

Selective Racking optimizes diverse storage space for goods>>> See details at: Standard European selective racking

Specifications:

- Load capacity: 2000 - 8000 kg per level.

- Maximum height can reach up to 15 meters.

- Upright frames use punched omega feet.

- Loading and unloading: manually or by forklift.

The entire system is electrostatically powder-coated according to European standards, reducing the risk of mold and corrosion while increasing shelf life.

Selective Racking is assembled with bolts, making it easy to disassemble, install, and move, meeting all usage needs.

Advantages

Why is Selective Racking the most widely used warehouse rack system today?

The rack can accommodate a wide range of goods with loads ranging from 2000 to 8000 kg per level, with different specifications, sizes, and models. This is the outstanding advantage of Selective Racking that no other pallet rack system has.

The open design allows for more aisle space, enabling forklifts to access pallets 100%. Additionally, the system's structure is compatible with all forklifts on the market, so businesses do not need to invest in additional specialized equipment.

Selective Racking is a flexible solution that can adjust sizes according to usage needs by moving the distance between beams. Moreover, it can be combined with other storage systems such as drive-in racks, mid-aisle racks, and industrial mezzanine racks, etc, maximizing unused space.

The structure is simple yet extremely robust, making the rack suitable for various methods of handling: manually, by forklift, or by ladder.

The Selective Rack facilitates easy access to pallets for forklifts

The Selective Rack facilitates easy access to pallets for forkliftsThe rack's multi-tiered structure allows goods to be neatly arranged, facilitating efficient sorting during warehousing operations, ensuring smooth operation of stored goods. Another significant advantage of Selective Racking is its investment cost: Selective Racking is relatively cheaper compared to other pallet rack models because it does not require much material for complex parts, is easy to manufacture, and does not incur additional costs for specialized forklift investment.

Disadvantages

The biggest drawback of this type of rack is that it only utilizes 40% of the warehouse space (due to the need for multiple aisles for forklifts). Therefore, if a business has a large amount of inventory, Selective Racking may no longer be the optimal solution, and instead, the business should consider options such as Drive-in Racking or Double Deep Racking.

II. Double Deep Racking

Characteristics

Structure:

Double Deep Racking has a similar structure to Selective Racking, with the only difference being that the number of rack components is doubled, and the two rows of racks must be back-to-back.

Specifications:

- Load capacity: from 500kg per level.

- Rack base frame: uses punched omega steel.

- Goods handling principle: LIFO (Last-In-First-Out).

- Loading and unloading: by specialized forklifts.

- The entire system is coated with two layers of electrostatic powder according to European standards.

Advantages

Industrial Double Deep racks can store homogeneous goods with heavy loads of up to several tons per level. They maximize storage space by being formed by two rows of Selective Racking, reducing half the number of aisles for forklifts compared to the Selective Racking system, thereby doubling the storage density of this type of rack.

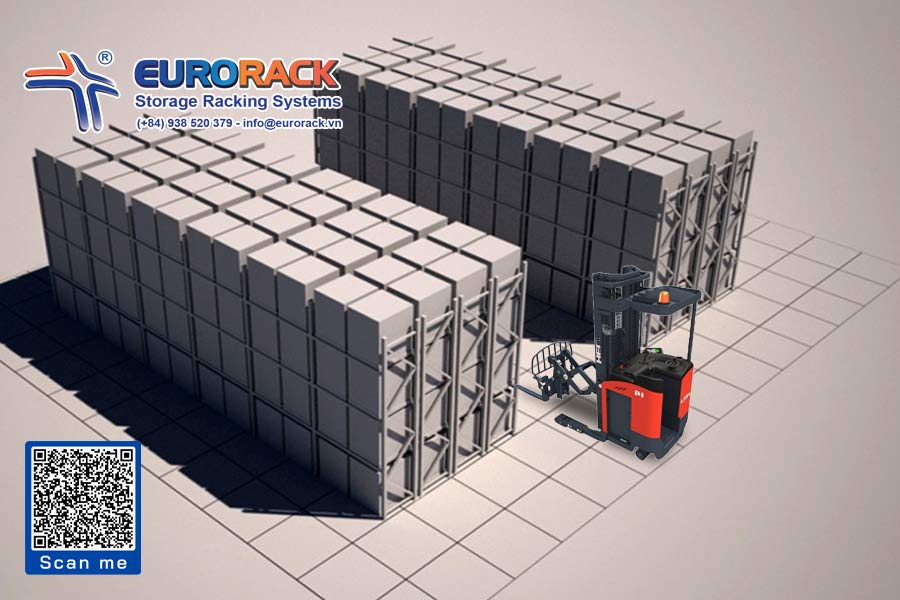

Double Deep Racking maximizes storage space

Double Deep Racking maximizes storage spaceIt offers high flexibility as the system is bolted together, making it easy to move and adjust the height of each tier to fit various needs.

Disadvantages

High cost: due to the doubled number of racks and the requirement for specialized forklifts, establishing a Double Deep Racking system requires a considerable investment for businesses. Access to pallets is limited to 50% due to the use of specially designed forklifts with optimized length, restricting aisle space.

Disadvantages of Double deep racking system

Disadvantages of Double deep racking systemApproaching pallets with a specialized forklift, equipped with optimally lengthened forks, limits the aisle space, thereby reducing pallet accessibility to 50%.

III. Comparison between Selective and Double Deep Racks

1. Similarities

Construction: Both have a relatively similar design, consisting of 6 basic components as previously mentioned.

2. Differences

| Comparison |

Selective Rack |

Double Deep Rack |

|

Accessibility to goods |

100% |

50% |

|

Storage density |

Optimizes floor space up to 40% |

Double the storage space of Selective racks |

|

Investment cost |

Low |

High |

|

Retrieval method |

Suitable for both FIFO (First In, First Out) and LIFO (Last In, First Out) methods |

Only suitable for LIFO |

From the above comparison, it can be seen that Double Deep racks offer double the capacity of Selective racks. However, due to their deep storage structure, the retrieval process must be conducted from the outside inward. Therefore, Double Deep racks are not suitable for items with a short shelf life.

In conclusion, both Selective and Double Deep racks have their own advantages and disadvantages, and evaluating which type of rack is best is challenging, as it depends on the specific needs. If you need to store a large, uniform quantity of goods with low selectivity requirements, Double Deep racks may be the suitable choice for you. Conversely, if you wish to store a variety of items with easy loading and unloading, where any forklift can operate, then Selective racks are the top choice.

Eurorack storage racking optimal warehouse space

Eurorack storage racking optimal warehouse spaceIV. Reputable Warehouse Rack Supplier in Vietnam

Having developed for over 14 years in the field of industrial storage racks, including Selective, Drive in, Double Deep, Push Back, Radio Shuttle, VNA, and ASRS, Eurorack is confident in being a reliable partner, offering the most efficient storage space solutions for every warehouse.

>>> Learn more: Eurorack Storage Racks

As a direct manufacturer without intermediaries, Eurorack commits to helping customers save up to 30% in production costs compared to market prices while still ensuring quality is 200% guaranteed.

Eurorack's storage racks optimize warehouse space with a perfect design according to ISO 9001:2015 quality standards, offering a wide range of models and sizes for customers to choose from and buy directly from the store. Customers can also place orders for custom designs that fit their warehouse layout. If you do not have a detailed layout, do not worry; Eurorack's staff is always ready to conduct surveys on-site and provide free drawings.

If you have a need for storage racks, let Eurorack find the most optimal solution for you!