Vietnam Pallet Flow Rack | Smart Storage System | Newest Quotes Of Eurorack JSC

Pallet flow rack is heavy-duty racking sysyem with roller design to move goods, limiting collisions. Learn "What is the flow rack? How does it work?" will help you determine if this is the optimal solution for your warehouse. Let's follow the article below!

Reduce a large number of aisles, the system optimizes storage space

What is pallet flow racking?

Pallet flow racking is the warehouse racking requires only one aisle for loading and one aisle for unloading. It is a high-density storage system that is capable of making the most of free space.

The pallets are placed high on the slide. Under the influence of gravity, they move to a lower position

What is pallet flow racking?

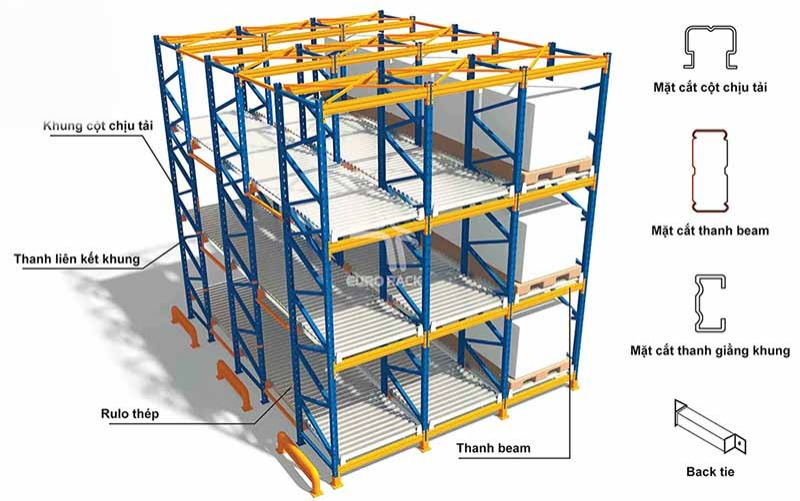

Structure and specifications of pallet flow rack

1. Structure

The pallet flow rack consists of 2 basic parts below:

Static rack structure

• Pillars: to bear the force of the whole system.

• Frame link bar: distributes the force between the load-bearing columns.

• Beam bar: connecting between two load-bearing columns and placing pallets.

Dynamic flow rail is a set of rollers placed along the length of rack, making pallets easy to move.

Note: The number of wheels depend on the flow and load of pallet. In case if there are less than 3 pallets in 1 lane, 1.9'' diameter steel wheel is most used. In contrast, for racking systems containing many pallets, a larger number of wheels with larger diameters will be used.

Flow rack uses rollers to operate the pallet, import and export quickly

2. Specifications

- Load capacity: Up to 1000kg/pallet (can be more depending on demand).

- The height can be up to 16m.

- Load-bearing column frame (pillars): Using omega pins for punching holes.

- Shelves: Using rails and rollers (rulos).

- Pick-up method: By forklift.

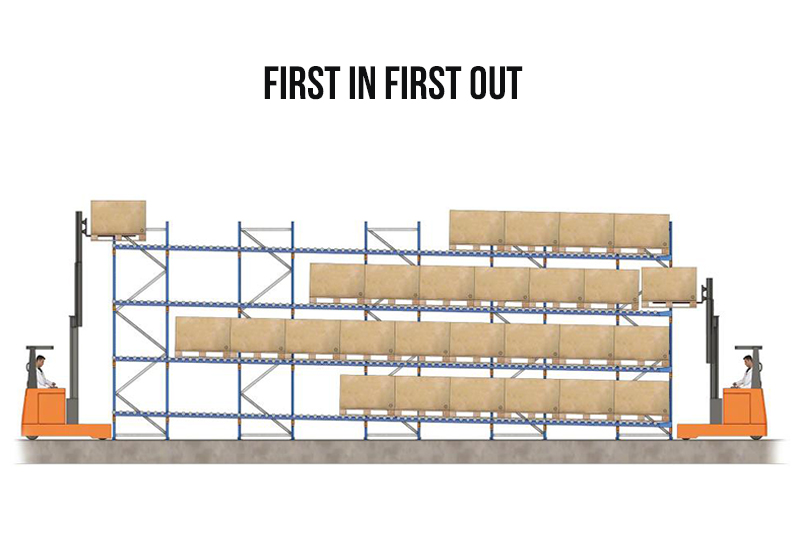

- Retrieval of goods: FIFO (First In First Out).

- Standard paint colors: Blue - Orange - Gray (can be changed according to customer requirements).

Types of pallet flow racking system

Based on lane design, flow racking is divided into 3 main types as follows:

Full width rollers: the ideal set of rollers for a wide range of product pallet sizes. They are full width also the most versatile pallet flow racking system option available on the market. Despite the cost of placing, it is convenient to transport many types of pallets.

Magnum roller: is the most durable pallet roller available today, very suitable for use in freezer storage. Magnum wheels are ideal for loads over 3,000 pounds/pallet.

Sliding wheel roller: this is the type commonly used with standard wooden pallets. Small in size, rollers are considered the most cost-effective pallet rollers.

Optimal height up to 16m, flow pallet racking store extremely goods

How does pallet flow racking work?

Flow rack uses rollers and force of gravity to move pallets from storage to where they are unloaded. They work according to the following principle:

1. Import process

Thanks to the gravity rack design. When the first pallet is put on the shelf, the pallet will automatically slide to the lower position. The process continues until the slide is filled with pallets.

The brake system equipped on the rack ensures that the pallet moves safely without deviating from the track.

2. Export process

Conversely, when the first pallet is removed from the system, the rear pallets move and fill the empty position.

As the forward-running pallets fill the slide, they stop and rest until unloaded from the system. This process continues until there are no pallets left on the slide.

How does pallet flow racking system work?

Why use pallet flow rack?

- Provides high-density storage.

- Good selectivity, can meet the storage needs of up to 20 pallets in depth.

- Store large volumes of homogeneous items.

- Control your inventory thanks to the FIFO principle.

- Turn inventory quickly, safely and efficiently. Pallets are loaded from one side, moved on the taxiway and unloaded from the opposite end.

Control warehouse according to FIFO, the system manages efficient warehouse

- Flow pallet racking does not require specialized forklift, any forklift is suitable for the system.

- Can be integrated with push back racking system to store a wide variety of items in limited space.

- It is very suitable for storing frozen goods, distributing food and consumer goods in large volume with continuous import and export speed.

Hold up to 20 pallets per slide, store large quantities of homogenous products

Eurorack's pallet flow racking - Vietnam's leading warehouse racking brand

Born and developed on a journey of more than 10 years, Eurorack is proud to be the first and most prestigious unit in Vietnam operating in the field of manufacturing and distributing warehouse racking in general, pallet flow racking. private.

Eurorack’s pallet flow rack is manufactured from 100% good quality and durable steel materials. That's why iron shelves have a lifespan of up to 15-20 years.

Eurorack provides modern flow rack, optimizing every big and small space

Flow pallet racking is specially machined by Eurorack. There, each design that Eurorack offers is the best solution for each individual warehouse space. Customers are completely assured, whether the space is large or small, Eurorack has the most optimal solution.

Taking the advantage of being a direct producer and distributor, the price is affordable, suitable for all sizes from small to large.

Each rack design Eurorack offers is the best option for each individual warehouse. Therefore, the flow pallet racking system will not have standard dimensions. Therefore, there will be no fixed list price. If you want to know the exact price list, you can contact the free hotline 0938.520.379 to receive the most detailed advice. Our staff is always ready to assist you 24/7.

In addition, when choosing Eurorack, customers also receive countless attractive incentives such as: free surveying costs, design and shipping support, and professional and fast installation support.

What is Pallet Flow racking? Hopefully, through the sharing above, customers will have more useful knowledge about this type of shelf. The last step, if you want to make full use of the warehouse space to store goods, let Eurorack be your companion!