What is Drive In racking? Advantages and Disadvantages

Drive In racking is the most commonly used heavy duty rack. Eurorack will support you find out what is Drive In system and its special applications. Thereby, deciding the most optimal design option for your warehouse.

What is Drive In rack system?

Drive In racking is a storage solution with extremely high density. Aisle space is minimized to increase the amount of stored goods, so forklifts move directly into the rack for loading and unloading. Each level has guide rails to guide and place the pallets inside the system.

The system is designed for single-size pallet warehouses and efficiently manage using the LIFO (Last In Fist Out) method.

What are Drive In rack specifications?

Specifications of Drive In pallet rack:

- Load capacity: 500 - 1000kg/pallet.

- Maximum height: 12m.

- Cấu tạo rail dẫn để chứa pallet.

- Store 10 - 20 pallets in depth or more.

- Foot frame: Omega.

- Method of loading and unloading: Forklifts.

- The entire system is powder coated according to European standards.

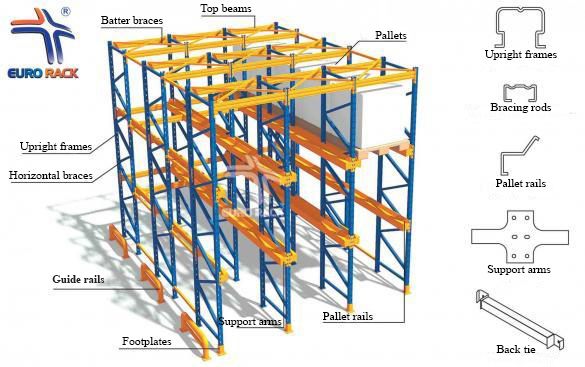

Structure of Drive In racking

Drive In pallet racking includes 8 basic components:

- Upright frame: Bear for the whole system.

- Horizontal brace: Disperse force between the upright frames.

- Top beam: Connect between 2 upright frames, because there is no beam.

- Batter brace: Support top beams connect upright frames.

- Footplate: Connect the upright frames to the floor and keep the system steady.

- Guard rail: Protecting the system from collisions.

- Support arm: Bear the pallet weight and disperse force to the upright frames.

- Pallet rail: Support to keep pallet stable

Advantages and Disadvantages of Drive In racking system

1. Advantages of Drive In rack

Drive In pallet rack have lots of advantages:

- Use up to 70% of the warehouse area.

- Extremely high density storage.

- Suitable for storing a large amount of homogeneous products

- Great solution for warehouses where you do not need to take exactly individual goods.

- Rack assembled with bolts, easy to change structure, move or upgrade as needed.

In many cases, enterprises often use this rack with Selective rack or Double Deep rack. This combination will help you store diverse items.

Drive In system capable of loading heavy goods up to 500kg/pallet

2. What are the disadvantages of Drive In racking?

Drive In pallet racking has some disadvantages:

- The system can only store one type of product, because it is difficult for forklifts to directly access goods.

- Drive In rack comply with LIFO, so it may cause some problems in inventory management.

- Because the forklift directly moves inside the sytem to pick up the goods, the driver must be careful to avoid colliding with the rack.

What are the use cases for Drive In racking?

Because Drive In rack has a some restrictions, it is just suitable for some cases:

- When you need to store large amounts of homogeneous products.

- You do not have to reach the goods directly.

- No matter the order of loading and unloading goods.

- Cold warehouses need to increase storage density to reduce operating costs.

Why you should choose Eurorack's Drive In?

Eurorack is one of the leading brands in manufacturing and construction of storage racking systems. Production process complies with ISO 9001: 2015, we meet European standards. Our production lines are imported from Europe and Japan.

Over 10 years of experience, we have constantly researched and applied new designs and technologies to production process to improve product quality. Eurorack's Drive In racking is always changing to bring the optimal solution for your storage system.

Drive In pallet racking projects of Eurorack.

Eurorack hopes that with the above information, you will know about Drive In racking and whether it is the optimal choice for your warehouse. If you have any question, contact us to get advice from our experts.

Contact Info:

Eurorack Mechanical Join Stock Company

Address: 5/3 Doan Thi Diem, Ward 1, Phu Nhuan District, Ho Chi Minh city

Phone number: (028) 39 953 088

Emai: info@eurorack.vn