What is selective racking? Advantages and Disadvantages

Selective racking system is the most commonly used heavy duty rack. It gives enterprises many advantages that other types of racking do not have. However, this system may not be the optimal storage solution for your business. To get the right choice, you have to learn about what is selective racking and its characteristics. Eurorack will help you through the following article.

What is Selective pallet racking?

Selective rack is a type of heavy duty rack and designed products through pallets. Goods are moved, loaded and loaded by forklifts. This system is commonly used in many industries and can withstand harsh storage conditions such as cold storage with a temperature of -600C.

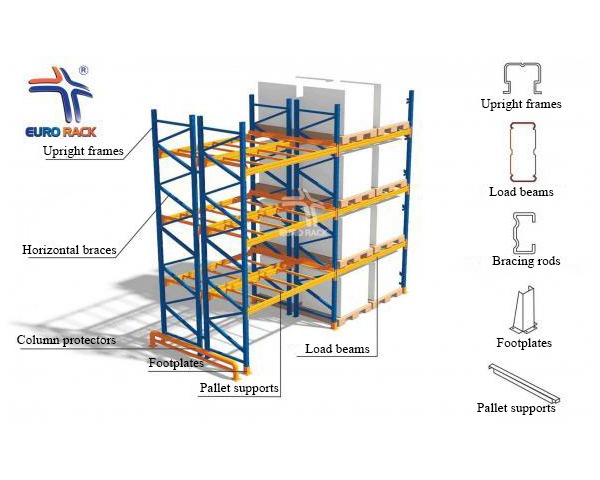

Structure of Selective rack

Selective pallet rack includes the following 6 basic components:

- Upright frame: Bear for the whole system.

- Horizontal brace: Disperse force between the upright frames.

- Load beams: Connect 2 upright frames and is the place to put pallets.

- Pallet support: Support load beams the keep pallets stable.

- Footplate: Connect the upright frames to the floor and keep the system steady.

- Guard rail: Protect the system from collisions.

What are Selective racking specifications?

Specifications of Selective pallet system:

- Load capacity: 500 – 6000 kg/level.

- Maximum height: 12.8m.

- Frame: Omega.

- Method of loading and unloading: Forklifts.

- The system can add steel wheels, wire wesh ... to support storage.

Selective rack is assembled by bolts, so you can disassemble, move the system as needed or change the height between levels based on the goods in your warehouse.

>>> RACKING QUOTES OF EURORACK <<<

Advantages of Selective racking

Selective rack can store a variety of goods with different specifications and sizes. Its design is flexible and can be changed according to products, so your warehouse's storage capacity is significantly improved.

Forklifts can directly access to individual pallets you need to take. This makes the transporting process fast and convenient. Inventory management is also simple.

Warehouse management does not need to follow FIFO or LIFO, as forklifts can directly access to each pallet and does not affect the others.

Selective rack's investment costs are lower than other systems. Because this racking is suitable for most types of forklifts, businesses do not need to spend a lot of money on loading and unloading system.

Note when using Selective pallet racking

Selective system only uses more than 30% of the warehouse area, so they take up a lot of space. If you need to store very large quantities of goods, this racking may not be the optimal solution for your warehouse.

Through the above article, Eurorack hopes they will help you understand what is Selective racking and its features. If you have any trouble in choosing the storage system, contact us to get free advice from our experts.

Contact Info:

Eurorack Mechanical Join Stock Company

Address: 5/3 Doan Thi Diem, Ward 1, Phu Nhuan District, Ho Chi Minh city

Phone number: 0938 520 379

Email: info@eurorack.vn