Top 8 Eurorack Heavy-duty storage racks | Safe and Cost-Effective

Choosing the right heavy-duty storage racks not only improves storage density but also significantly saves warehouse management costs. Depending on the industry, businesses may decide to invest in different types of racks. Let's explore the 8 most popular rack models today with Eurorack to make the best choice!

|

TABLE OF CONTENT |

Characteristics of Heavy-Duty storage racks

Heavy-duty storage racks are designed to hold loads of more than 500kg per pallet. They are manufactured from high-quality, sturdy steel, capable of withstanding heavy weights and ensuring durability. The heavy-duty racks utilize pallets to secure the position of goods before being placed on the rack. Loading and unloading activities are primarily carried out using forklifts.

1. What is a heavy-duty storage rack?

A heavy-duty storage rack is a type of pallet rack used to store items with high load capacities. Therefore, the rack will have strong support columns, robust frames, and sturdy beams to secure the goods. Heavy-duty racks are made from premium, sturdy, and durable steel, meeting the requirements for storing heavy loads in most industrial warehouses today.

The components of the rack are mainly connected by bolts and nuts, facilitating structural modifications when necessary. The entire steel frame is powder-coated to prevent rust and damage caused by environmental factors.

On average, each pallet holds about 500kg, with each level accommodating 2 to 8 pallets. This means that the total load on one level can reach up to 1000kg, or even 2000kg, 3000kg, or 4000kg. Therefore, it is not surprising that heavy-duty racks are a familiar product for warehouses with heavy-duty storage needs.

2. Structure and role of Heavy-Duty racks

Depending on the warehouse, investors can come up with reasonable and intelligent installation solutions. To find and apply the appropriate type of heavy-duty racks, you need to understand some basic information about their structure and role.

Structure:

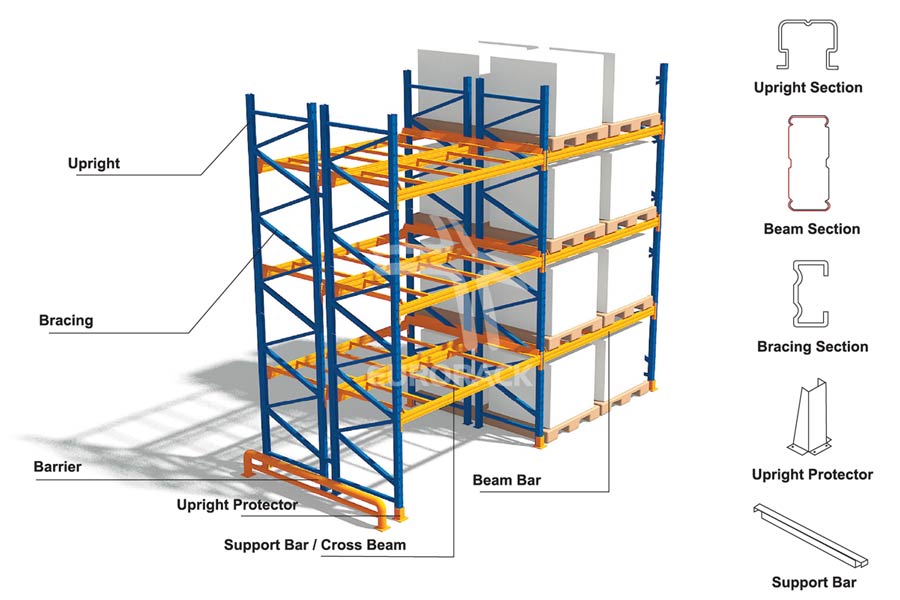

Except for cantilever racks, most heavy-duty storage racks consist of the following main components: Uprights, support bars, braces, beams, and guardrails. To facilitate easy assembly and movement when necessary, heavy-duty warehouse racks are primarily connected by bolts and nuts.

Additionally, the entire steel frame of the rack is powder-coated. Thanks to this surface treatment method, heavy-duty racks can resist damage and rust. They are durable and have an average lifespan of 15 to 20 years, optimizing investment costs while achieving the desired efficiency.

Role:

In the context of warehouses "springing up like mushrooms", with increasing storage demands, heavy-duty racks are considered the "savior" for investors. The reason why businesses favor this type of rack lies in the benefits it offers. Let's take a look at some of the important functions of heavy-duty warehouse racks with Eurorack:

Optimize warehouse space: When a company thrives and starts to expand, with a massive amount of goods being stored and retrieved, warehouse space becomes limited. To overcome this, heavy-duty racks help investors optimize warehouse space, increasing storage capacity.

Manage goods: More warehouses and more goods mean that warehouse managers face the challenge of controlling the system. By using heavy-duty racks, you will no longer face numerous difficulties and challenges as goods are now categorized and neatly arranged. This minimizes the likelihood of loss or damage.

Support quick goods handling: Using heavy-duty racks allows forklifts to load and unload goods quickly.

Overall, the greatest benefit of heavy-duty racks is optimizing resources, saving time and costs for businesses. This is also the desire of any entrepreneur.

The 8 most popular Heavy-duty storage racks today

1. Selective Racks

The Selective Racking system is a type of rack that uses pallets for storing goods. Its outstanding advantage is the creation of wide aisles (averaging 3 to 3.5 meters), allowing standard forklifts to move freely within the range of goods retrieval. Because of this, the rack is also known as an independent heavy-duty storage rack.

Applying the pallet selective racking system provides warehouses with the capability to continuously retrieve pallets, speeding up the import and export process while still ensuring 100% accurate access to goods. Additionally, the system optimizes height from 6m to 8m, with a load capacity of 1000kg to 3000kg per pallet.

Today, Selective pallet racking system is an optimal solution for warehouses storing a variety of goods. The structure of the Selective rack is relatively simple compared to other types of racks. Therefore, when there is a need to adjust the spacing between the tiers, the operation is very convenient.

Selective racks are applied in various types of warehouses, such as those for raw materials, industrial production supplies, food storage, consumer goods, and fabrics. The installation cost of Selective racks is not high, helping businesses save significantly.

> > > See more: Specifications and Applications of Selective Racking

2. Drive In racks

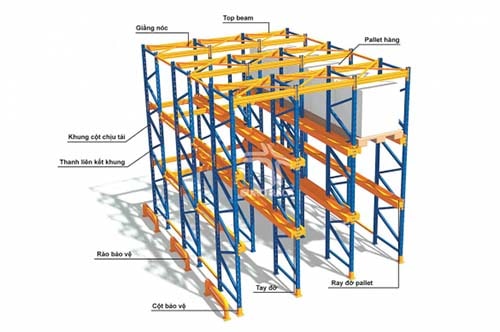

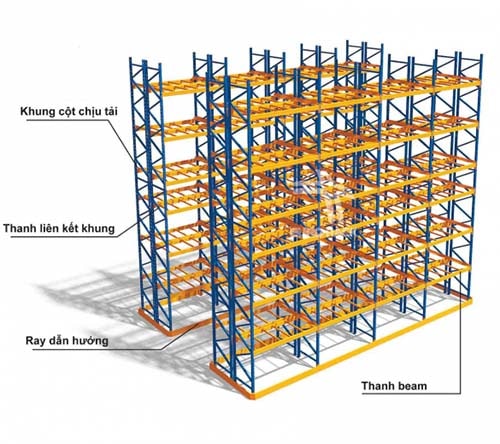

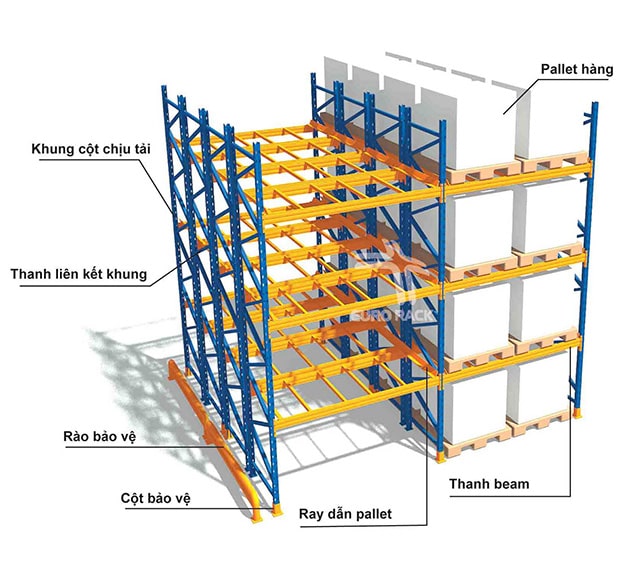

The Drive-In Rack (Drive through racking) has a height of up to 12 meters, ensuring optimal space utilization in the warehouse. Since the rack eliminates the need for aisles between rows, more than 70% of the warehouse floor area is used to improve storage density.

The structure features rails that guide the pallets, storing large quantities of homogeneous goods in depth. On average, each pallet on a Drive in pallet racking holds between 500kg and 1000kg. The rack only uses a single aisle, allowing it to be placed against the wall to save even more space.

If you want to apply the LIFO (Last In - First Out) principle, a popular storage method in food, beverage, and cold storage warehouses with temperatures as low as -60 degrees, then you should choose Drive in racks for your warehouse.

It is important to note that depending on specific requirements, the measurements and design specifications of Drive in racks should be tailored to achieve the best results.

Video: The process of using a forklift to load goods onto Eurorack's Drive-In racks | Raw Material Warehouse Project

3. VNA racks

The VNA (Very Narrow Aisle racking) rack is a type of steel rack with narrow aisles, where the aisle width between racks is reduced to 1.7m - 2.2m. The forklifts used between these rows are three-way forklifts, allowing convenient loading and unloading of goods without needing to turn around.

The outstanding advantage of the VNA rack compared to other types of racks is its ability to optimize height up to 17 meters, effectively utilizing the warehouse's roof height to improve storage capacity.

VNA racking shares many advantages similar to Selective racking: the ability to store a wide variety of products and the efficiency of forklifts in directly accessing each pallet location with near-perfect accuracy.

However, due to the narrow aisles, the forklifts used need to meet specific requirements: they must maneuver well in tight spaces and have a high reach to meet the demands of loading and unloading goods at height. As you may know, the investment cost for these specialized forklifts is quite high.

4. Double Deep racks

The Double Deep Rack is created by combining two rows of heavy-duty Selective racks side by side. As a result, this rack type inherits most of the advantages of Selective racking. The key difference, and also its standout feature, is that Double Deep racks offer better storage capacity than Selective racks.

Double Deep racks have a depth of 4 pallets, with each pallet capable of holding up to 1000kg. This is an excellent solution for warehouses that need to improve inventory flow while still ensuring 50% loading and unloading efficiency.

> > > Learn more about the outstanding advantages of double deep racking compared to selective racking here.

This type of racking is commonly used in warehouses for agricultural products, food storage, and electronic component storage. In many cases, warehouses can combine Selective and Double Deep racking to maintain optimal warehouse operations.

Not only is it intelligently applied in regular warehouses, but Double Deep is also an optimal solution for refrigerated and frozen storage warehouses. This is due to the robust steel construction and the rack's high resistance to harsh environments.

5. Mold Rack

The heavy-duty mold rack is a steel frame rack designed in a drawer-style, specifically for managing heavy molds weighing 1500 - 3000kg per mold. The molds are equipped with wheels for easy sliding in and out. For safe loading and unloading, the steel rack is also equipped with an additional crane to support stable goods handling.

In addition to the drawers being equipped with wheels for powerful sliding, the drawers on the rack also operate in a safe, static state thanks to specialized deceleration devices when subjected to heavy loads. Therefore, they are absolutely safe.

The steel rack series is known for its durable load-bearing capacity, with metal surfaces treated by powder coating, making it resistant to external factors. As a result, warehouse owners can effectively utilize their investment budget thanks to the durability of the mold rack.

For specialized storage warehouses such as those for heavy-duty spare parts, mechanical equipment, machine structure management, shipbuilding materials, and automotive manufacturing, mold racks are the only suitable storage organization solution.

6. Cantilever rack for storing heavy and bulky items

The Cantilever rack, or arm rack, is a steel rack specifically designed to store long, oversized, and irregularly shaped heavy items such as steel, plastic pipes, wooden boards, and furniture.

The steel rack is constructed with arms that extend up to 2.5 meters, with a maximum load capacity of 1000kg per arm. Typically, the load capacity per level of a cantilever rack ranges from 8000 to 9000kg.

The advantage of the cantilever rack for bulky items is that the arms create an open front, unobstructed by columns, making it easier to load and unload goods. The application of cantilever racks allows for the addition of steel panels or plywood shelves to store smaller-sized goods.

To provide the most optimal solution for each warehouse, industrial cantilever racks can be customized in terms of arm length, the number of arms per level, and the number of levels to best suit the specific needs.

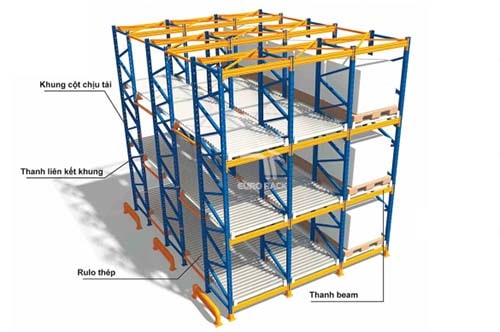

7. Pallet flow rack

The pallet flow rack is a heavy-duty rack with a special design featuring a system of rollers placed on an inclined frame (<3 degrees). This unique structure creates a gravity flow on the rack, allowing pallets to move smoothly from a higher to a lower position.

Flow racks do not require aisles between rows, thus allowing for high-density storage. The quick pallet turnover is facilitated by the roller conveyor, saving over 40% of handling time compared to conventional racking systems.

The advantage in loading and unloading time is significantly improved with this storage system. Additionally, the inclusion of a braking system ensures that the handling process is absolutely safe.

This pallet rack system, subjected to strict safety inspections, provides an ideal storage solution for many industries, including food, beverage, and pharmaceutical storage. It is especially suitable for large-scale production material warehouses.

> > > See more at: Pallet flow racking system

8. Push Back rack

The heavy-duty Push Back rack also operates on the principle of gravity. It features an inclined design but uses sliding carts to manage loading and unloading from one side. These sliding carts facilitate the easy movement of pallets in and out of storage, reducing handling time.

Each storage line holds 2 to 5 pallets in depth. With an average load capacity of 500 - 1000kg per pallet, the Push Back rack is an excellent solution for warehouses needing to increase storage capacity while managing loading and unloading from a single direction.

Eurorack heavy-duty storage rack pricing

The variety in models, structural features, and technical specifications of heavy-duty racks leads to different investment costs for each design. Furthermore, each solution is truly optimal when it is directly surveyed and custom-designed.

To help customers estimate the investment costs for standard rack installations, we invite you to review our general pricing table for storage racks. Please note that the pricing information is for reference only; depending on specific cases and the time of the quotation, the cost of heavy-duty storage racks may vary.

> > > Refer to: Warehouse racking system quote

To receive an accurate quotation for heavy-duty racking system, Eurorack hopes to hear your specific needs. Based on your warehouse layout and other criteria, our experienced technical team will provide the optimal solution along with a complete quotation for your warehouse.

Where to buy reliable heavy-duty racks in Viet Nam?

Eurorack is proud to be a leading brand in the production and installation of storage racks that meet ISO 9001:2015 standards. Eurorack operates with mechanical fabrication lines imported from Europe and Japan, along with a professional staff.

Meeting the highest standards, Eurorack storage racks have received exclusive registration and are trusted by many major brands: Nestle, Vinamilk, Coca Cola, Pepsico, DKSH, Frieslandcampina, and Lotte Mart, among others.

Continuously striving and advancing, we offer you a complete and automated production process with multiple stages. This approach minimizes processing costs, delivering high-quality storage solutions directly to customers without intermediaries.

Images of Eurorack's Real Projects

As technology becomes increasingly prevalent in many industries, including storage and inventory management, many warehouses and factories are shifting towards the installation of semi-automated robot racks. These systems offer smart inventory management, handling loading and unloading at a speed of 35m/min, ensuring absolute safety through modern robotics technology.

Robot racks, also known as Radio Shuttle racks, from the Eurorack brand, can handle loads of up to 3000kg per pallet, with pallets operating at a speed of 40m/min. This allows forklifts to load and unload goods continuously and quickly. This is also one of our key heavy-duty rack products.

Unloading thanks to automatic sensors

Important considerations when purchasing heavy-duty racks

Given the benefits that heavy-duty racks offer, warehouse owners are likely interested in purchasing suitable racks for their facilities. To select the desired type of rack, readers should consider the following factors:

Purpose, Space, and Warehouse Area:

Heavy-duty racks can be applied in various types of warehouses. Therefore, before purchasing racks, warehouse owners should determine the intended use as well as the space and area of their warehouse.

Products to be Stored

Although some racks can accommodate a wide range of products, it is best for investors to choose racks based on the specific goods they need to store.

Sturdiness and Load Capacity of the Rack

Lastly, the load capacity and durability of the rack are crucial factors that businesses should carefully consider when purchasing. Durable racks help investors avoid the need to spend on frequent improvements or replacements.

We hope that the above information will help you find the right heavy-duty rack for your warehouse. If you have any questions, please contact Eurorack directly for free expert consultation.

Contact Information

Eurorack Mechanical JSC

Tel: 0938 520 379

Email: info@eurorack.vn

Address: 5/3 Doàn Thi Diem, Ward 1, Phu Nhuan District, Ho Chi Minh City, Viet Nam